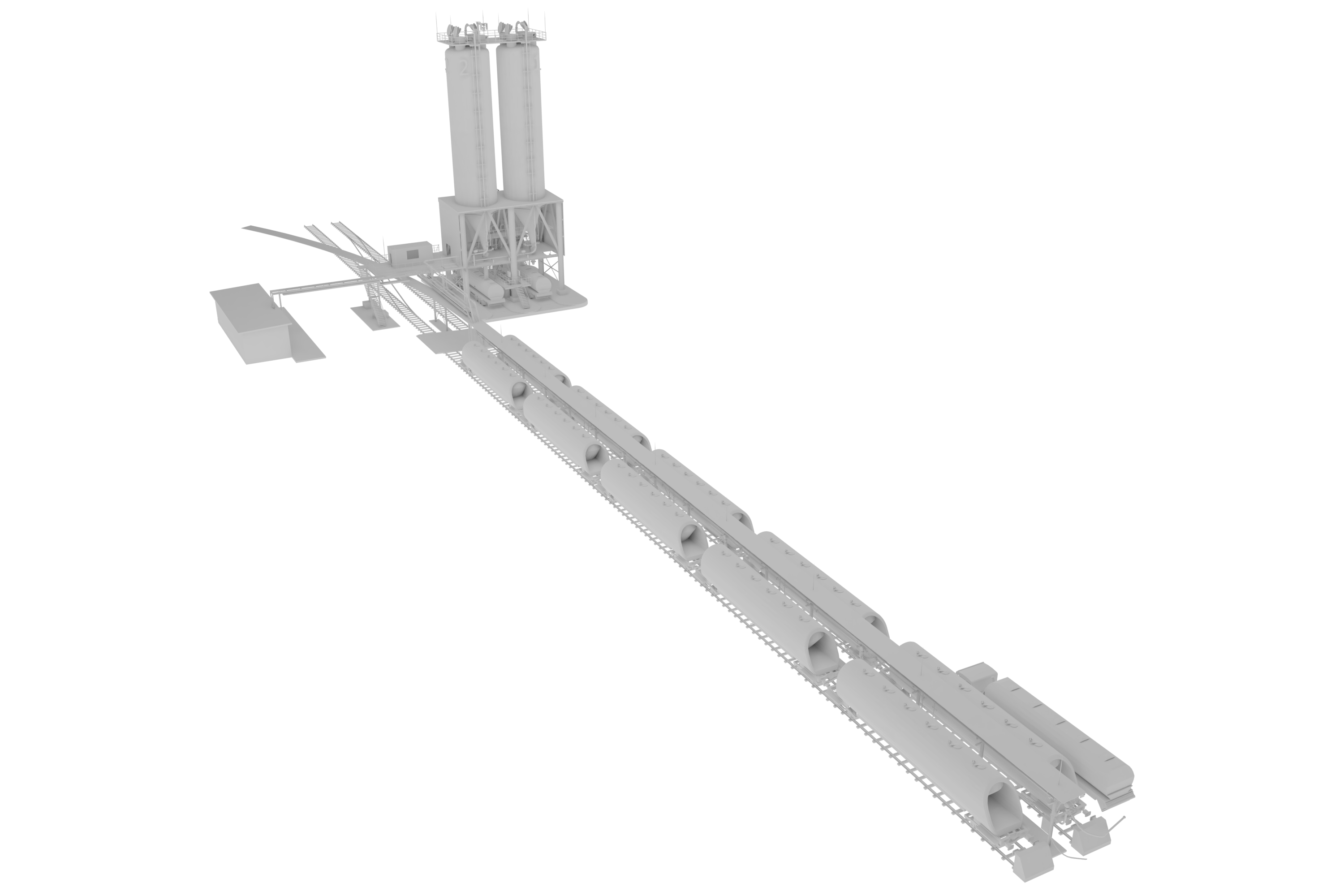

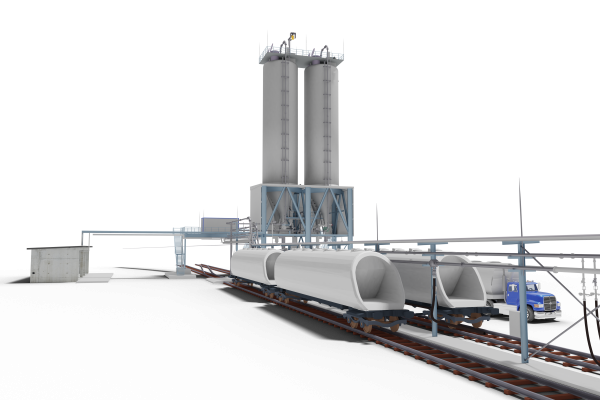

The transport of bulk materials takes place for reasons of cost , as well as for environmental compatibility, increasingly in silo cars by train. The regional distribution of bulk goods is carried out by appropriate truck silo vehicles. The transshipment facilities form the link between the transfer from rail to road. We are your specialist for the design and implementation of your rail unloading systems, regardless of which bulk material you are dealing with. From manual single unloading to automatic block train handling, we have realized a large number of systems.

Experience

- Rail wagons and rail wagon unloadings accompany STAG since its foundation in 1954. The experience gained since then is immense.

Special Features – Applications (USPs)

- simple to extend

- STAG Dense flow pipes

- easy assembly due to prefabricated elements

- degree of automation freely selectable

- service- and maintenance friendly construction

Branches

- Chemistry

- Construction material handling

- Rocks and Earth

- Lignite handling

| conveying capacity | conveying distance | number of rail wagons | automation | construction |

|---|---|---|---|---|

| till 150 t/h | till 300 m | 10 piece | semi-automatic / manual | covered / free standing |

At the site of Brandenburg, STAG has been entrusted by Rheinbraun Brennstoff GmbH to build a terminal serving for the transhipment of pulverised lignite from rail to road. STAG was responsible for the engineering, construction, assembly and successful commissioning of the overall plant.

During their long-year partnership, Holcim (Schweiz) AG and STAG have already implemented most various conveying systems for bulk products all over Europe.

On behalf of Arge Transco Sedrun, STAG engineered, built and successfully commissioned, in 2003, an extraordinary transhipment plant for bulk products such as cements, ashes and microsilica necessary for the construction of the world’s longest railway tunnel.