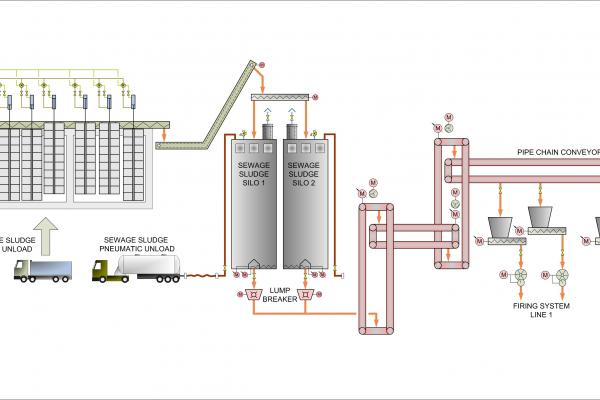

During their long-year partnership, Holcim (Schweiz) AG and STAG have already implemented most various conveying systems for bulk products all over Europe.

Based on STAG‘s experience of many years in the bulk material conveying technology, in particular in the handling of dust-explosive bulk products such as lignite, dry sewage sludge and animal meal, several innovative plants have been designed and successfully commissioned at the Untervaz site.

Particular highlights are the systems for the supply, storage, dosing and pneumatic dilute and dense conveying of cements, animal meal, dry sewage sludge, lignite dust, plastic chips, various additives as well as the gravimetric dosing od iron(II) sulphate.

Applied Main Components

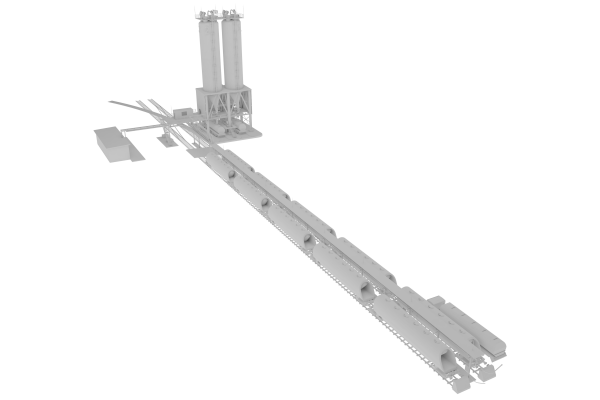

• Trough chain conveyor

• Proportioning belt weigher

• Silo plant including equipment

• Pressure conveying vessel

• Butterfly valve

• Rail wagon unloading station

• Silo vehicle unloading station

• Pressure conveying vessel (tandem operation)

• STAG conveying line system DENSEFLOW

• Fluidised intermediate hopper

• Differential dosing unit

• Compressor and ventilation stations

• Inertisation facility

Particularities

• The lignite and animal meal/dry sewage sludge plant has been engineered, built and successfully commissioned according to the ATEX Directive 2014/34/EU.

• Alternative fuel plant

• Iron(II) sulphate dosing plants for chromate reduction

• Direct cooperation with the operating company

Client

• Holcim (Schweiz) AG, Untervaz site

| Systems | Conveying rate | Conveying distance |

|---|---|---|

| Rail wagon discharge of lignite dust | 4 x 50 t/h | 60 - 220 m |

| Dense phase conveying of lignite dust into intermediate silo | 25 t/h | 410 m |

| Dense phase conveying of iron(II) sulphate to dosing station | 3.5 t/h | max. 210 m |

| Iron(ll) sulphate dosing (per station) | 1.5 t/h | - |

| Dense phase conveying of cement into storage silo | 23 - 40 t/h | 190 m |

• Rail wagon unloading station

• Combined dense phase conveyances of cement and granulated slag

• Dilute phase conveyances of alternative fuels

• Gravimetric dosing systems for iron(II) sulphate / alternative fuels

• Silo plants including equipment

• Silo discharge systems

| Bulk Material | Grain size | Moisture content | Bulk density | Temperature | Property |

|---|---|---|---|---|---|

| Lignite dust | 60 µm | 11 % | 0.5 t/h | 20 °C | little abrasive |

| Dry sewage sludge granulate | 4 mm | 90 - 93 % | 0.75 t/m³ | 45 °C | abrasive |

| Animal meal | - | 96 % | 0.6 t/m³ | 45 °C | abrasive |

| Lime dust (filler) | 8 µm | < 0.3 % | 0.8 t/m³ | 20 °C | abrasive |

| Cement | 5 µm | < 1.0 % | 1.0 t/m³ | 130 °C | little abrasive |

| Granulated slag | 8 µm | < 1.0 % | 1.0 t/m³ | 130 °C | little abrasive |

Steinmüller Babcock Environment, based in Gummersbach, is realising the construction of the new waste-to-energy power plant in San Sebastian, Spain.

For financial and ecological reasons, silo rail wagons are increasingly used for transporting bulk products. The regional distribution of these bulk products is ensured by appropriate silo trucks. The transhipment systems constitute the link for transhipment of materials from rail to road.

Each year STAG handles around 500 customer orders and achieves satisfied customers around the world. Here too, the focus lies on life-cycle-oriented warehousing as well as the plant availability. The experienced employees of the business area service are happy to answer any questions or suggestio