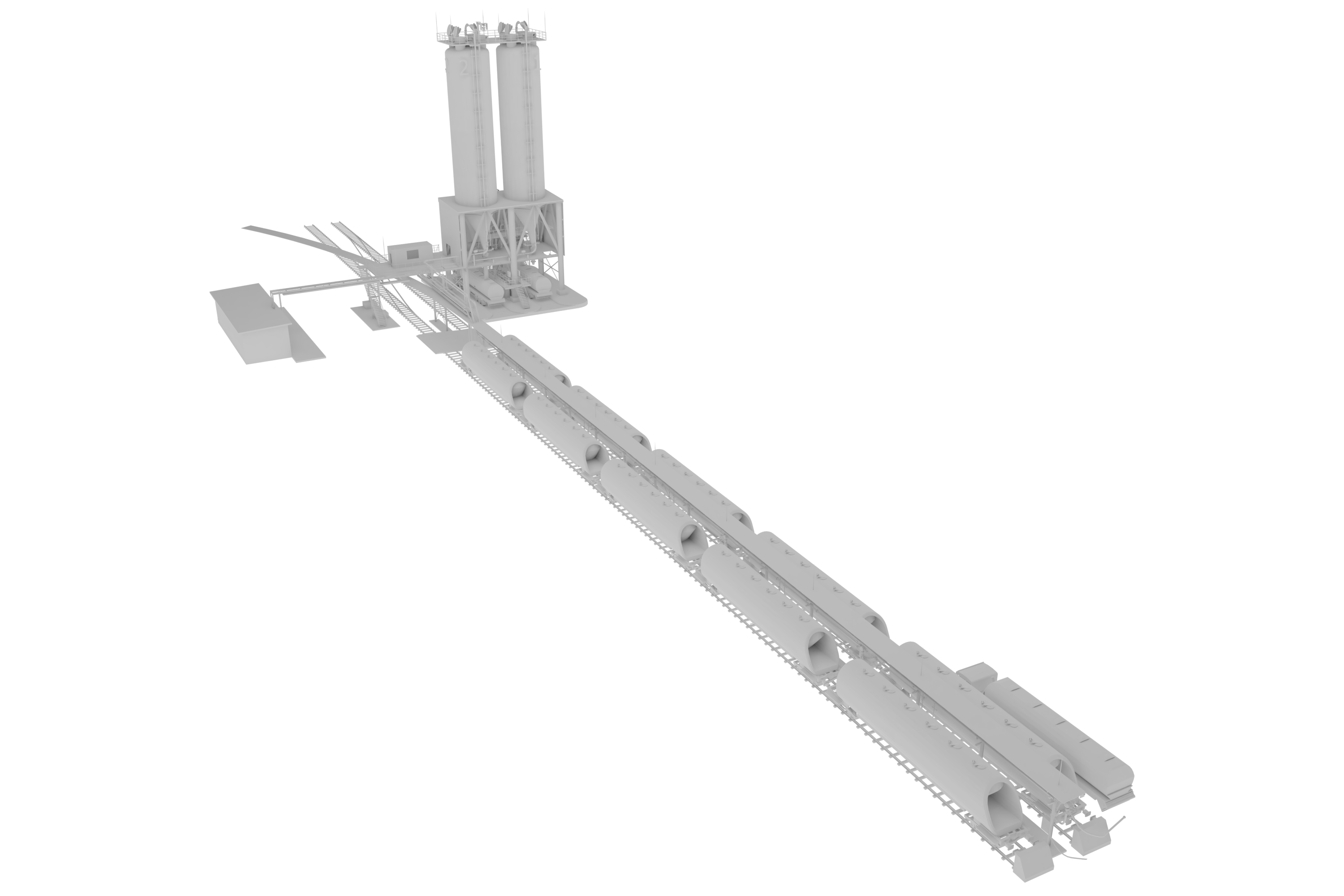

For financial and ecological reasons, silo rail wagons are increasingly used for transporting bulk products. The regional distribution of these bulk products is ensured by appropriate silo trucks. The transhipment systems constitute the link for transhipment of materials from rail to road. We are your specialist regarding the conception and realisation of your rail wagon discharge system, irrespective of the particular bulk material. STAG has realised a wide variety of systems, ranging from a manual single discharge system to an automatic block shipment of rail wagons.

Experience

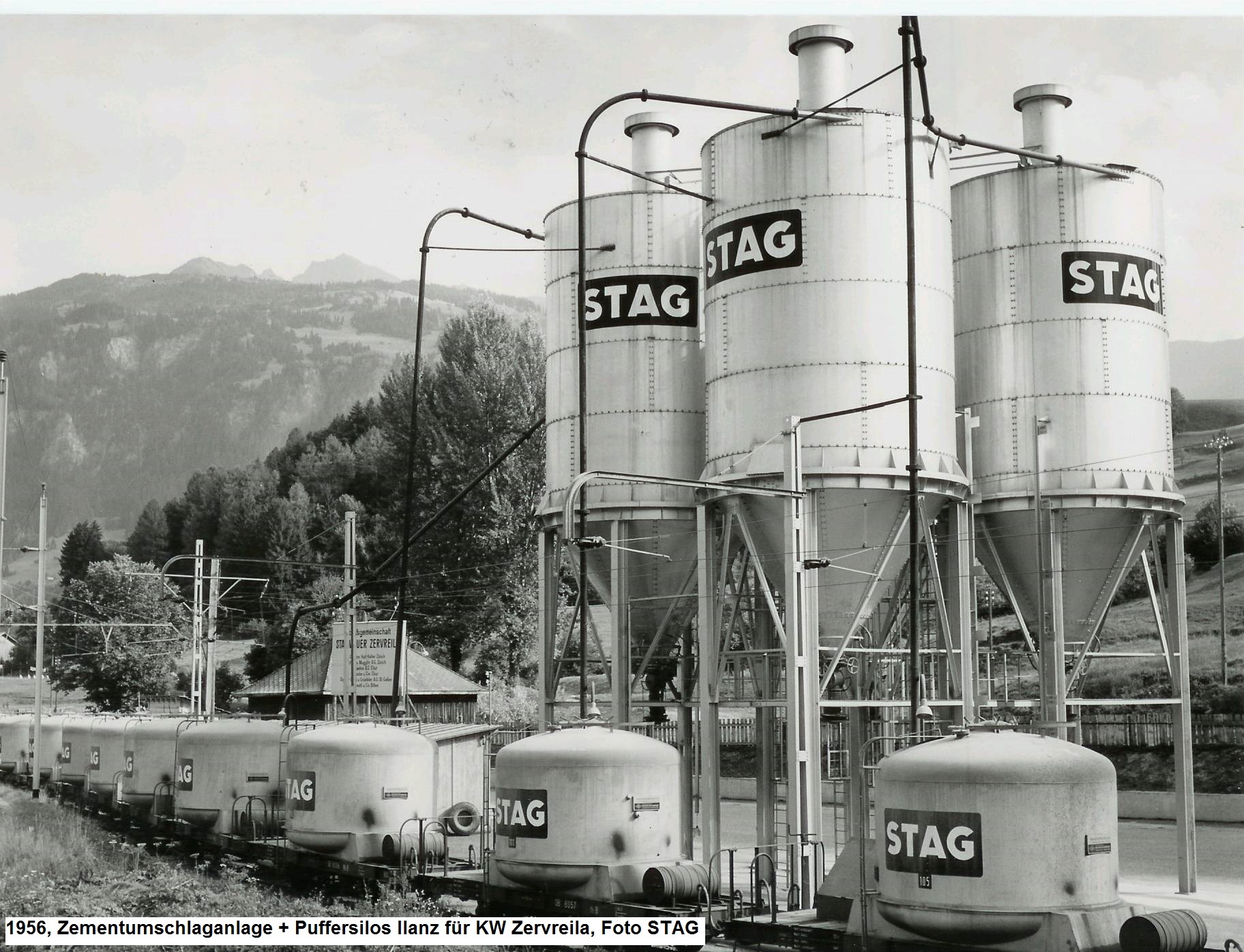

- Since its foundation in 1954, STAG has been engaged in the field of rail wagons and rail wagons discharge. The experience and expertise we have acquired since are tre-mendous.

Special Characteristics – Application (USP)

- Easy expansion

- STAG dense phase tubes

- Easy assembly due to prefabricated elements

- Level of automation to be chosen at will

- Construction easy to maintain and to inspect

Industries

- Chemical industry

- Construction materials handling

- Rocks and earth

- Lignite handling

Depending on the respective requirements, two material connections and one conveying air connection are installed for each rail wagon in order to ensure the rail wagon unloading. The number of rail wagon connections may be selected at will and is depending on the local condi-tions. The rail wagon unloading into the target silos takes place using the dense phase method. The necessary conveying air is provided by a compressor unit. All electronic components, such as silo filling level, silo selection, etc. are monitored and operated via a control cabinet.

| conveying distance | output | Number of railway silos | automation | method of construction |

|---|---|---|---|---|

| bis 300 m | bis 150 t/h | 10 | automatic / semi-automatic | covered / free standing |

Bulk products: cement, lime, plaster, micro silica,

fly ash, terephthalic acid, lignite, etc.

Conveying distances up to 300 m

Conveying rates up to 150 t/h

Deflection systems to silos: STAG shunting and diverter pots

Pneumatic discharge

Dense phase conveying system

Material connection DN 125 (standard)

Air connection DN 100 (standard)

| Förderdistanz | Fördermenge | Anzahl Bahnwagen | Automatisierung | Bauweise |

|---|---|---|---|---|

| bis 300 m | bis 150 t/h | 10 | automatisch/ halbautomatisch | überdacht/ frei stehend |