The general contractor Rafako from Poland supplied for the first time a complete boiler and electric filter system for the waste-to-energy power plant in Stettin and therefore, opted for the expertise of STAG.

As a classic supplier of mechanical and pneumatic boiler and electric filter ash removal systems,

STAG is in charge of the engineering, production, commissioning of the plants as well as of the training of the operational staff.

Applied Main Components

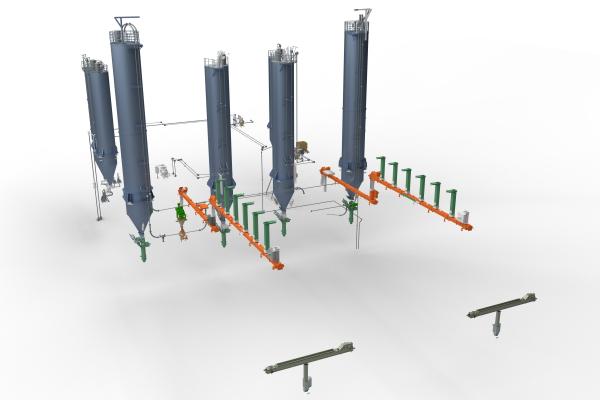

• Trough chain conveyor for ash discharge 2./3. boiler train

• Trough chain conveyor

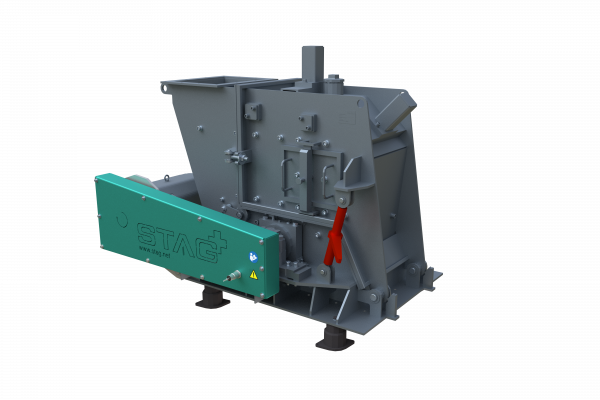

• Impact mill

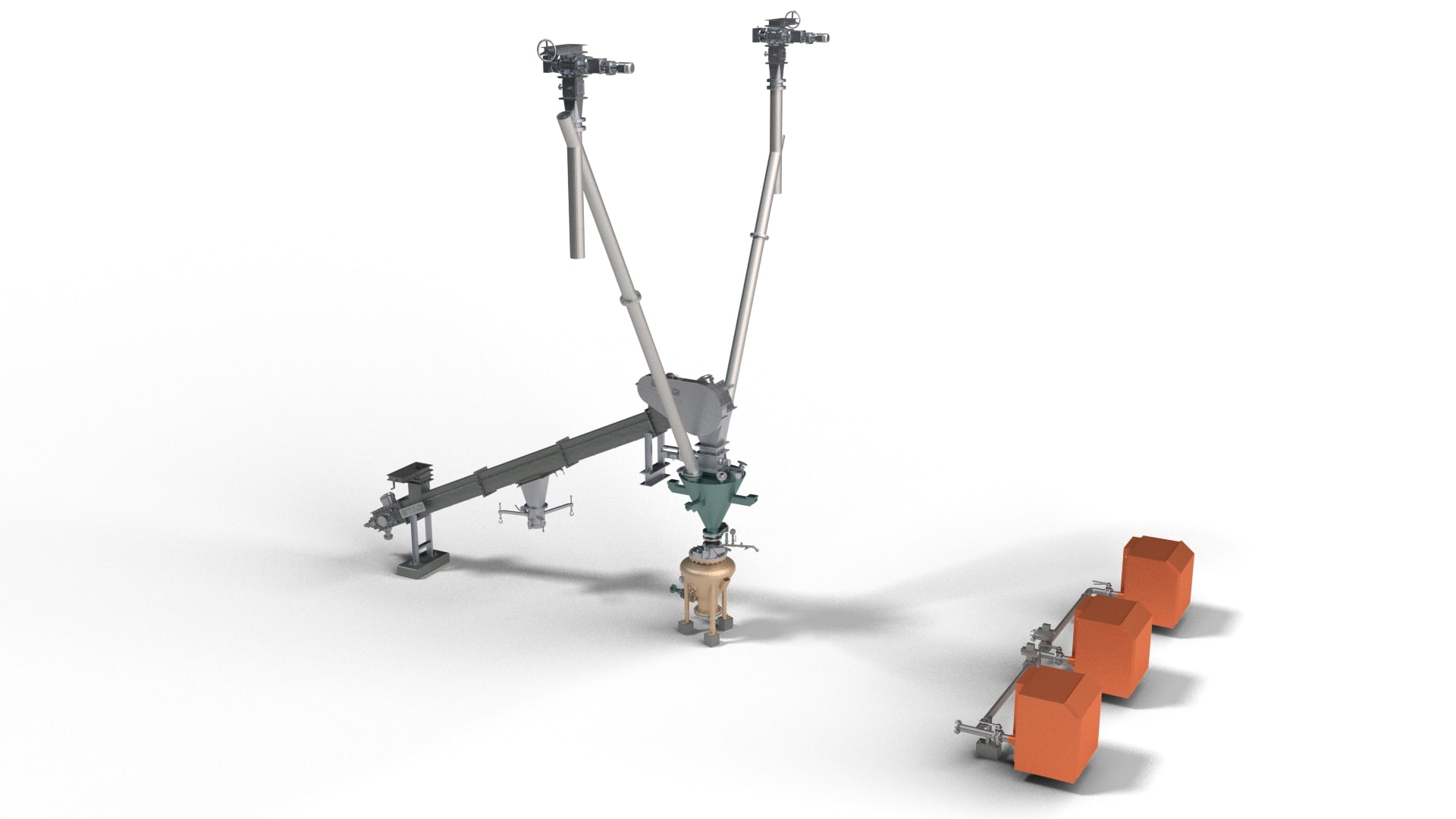

• Pressure conveying vessel

Particularities

• Fluidisation basin for the filling of the tandem pressure conveying vessel

Client

• RAFAKO S.A

| Systems | Conveying rate | Conveying distance |

|---|---|---|

| Boiler ash removal 2./3. pass and 4. pass | 1.0 t/h | 95 m |

| Electric filter ash removal | 0.5 t/h | 60 m |

- Mechanical/pneumatic boiler ash removal

- Mechanical/pneumatic electric filter ash removal

| Bulk Material | Grain size | Moisture content | Bulk density | Temperature | Property |

|---|---|---|---|---|---|

| Boiler ash 2./3. pass and 4. pass | 0.01 – 5 mm | < 0.1 % | 0.6-1.2 t/m³ | 200-450 °C | abrasive |

| Electric filter ash | sehr fein | trocken | 0.6-1.0 t/m³ | 220 °C | abrasive |

Based on their long cooperation in the area of conveying systems for thermal waste treatment plants, Hitachi Zosen Inova and STAG have already realised several projects together. In 2015, a completely new waste treatment plant featuring two lines has been put into operation in Perlen (CH).

The impact mill has been specially designed for breaking up agglomerated material within the bulk product. This application is mainly used in the treatment of boiler ash originating from incineration plants.

Each year STAG handles around 500 customer orders and achieves satisfied customers around the world. Here too, the focus lies on life-cycle-oriented warehousing as well as the plant availability. The experienced employees of the business area service are happy to answer any questions or suggestio