Based on their long cooperation in the area of conveying systems for thermal waste treatment plants, Hitachi Zosen Inova and STAG have already realised several projects together. In 2015, a completely new waste treatment plant featuring two lines has been put into operation in Perlen (CH). This plant is one of the most modern and innovative installations throughout Europe.

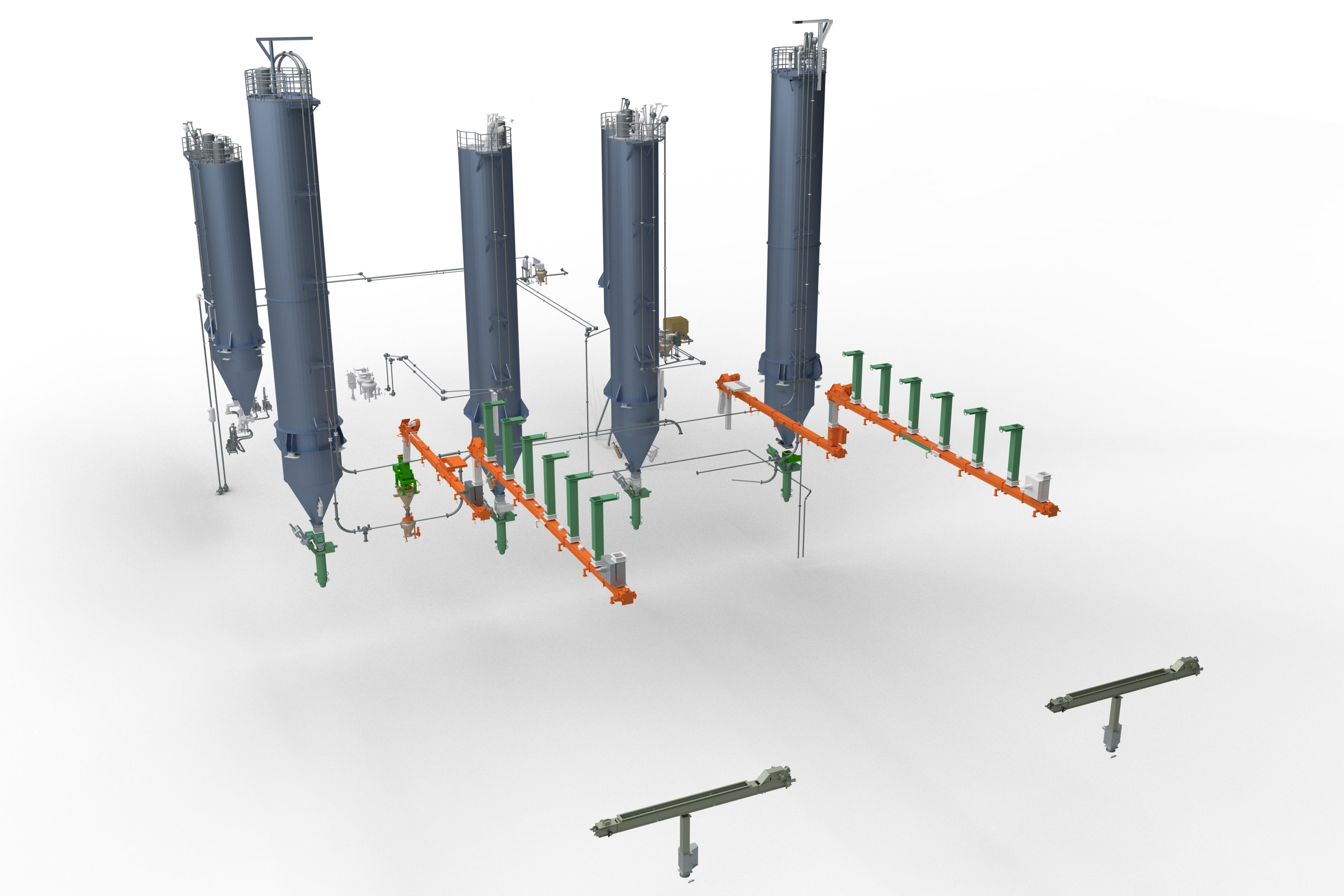

The approach of combining mechanical and pneumatic conveying technology makes STAG an ideal partner.In cooperation with HZI, STAG was responsible of the engineering and supply of the overall mechanical and pneumatic ash removal systems for boiler, electric and fabric filters, including loading silos equipped with a truck loading system, as well as of the overall hydrated lime and hearth furnace coke injection for flue gas treatment. The engineering and supply of the bicarbonate silos, including the equipment, of the bicarbonate mills and their pneumatic transport facility to fabric filters was also carried out by STAG.

Applied Main Components

• Trough chain conveyor

• Double pendulum flaps

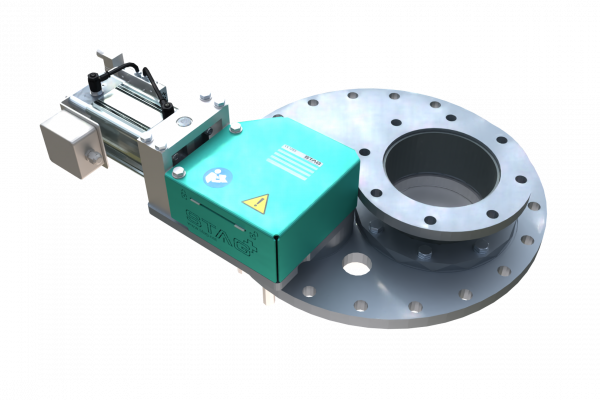

• Pressure conveying vessel

• Impact mill

• Roots blowers

• Silo including equipment

• Dosing unit

• Tube screw conveyors

• Rotary vane feeders

• Butterfly valve

Client

• Hitachi Zosen Inova

• Renergia

| Systems | Conveying rate | Conveying distance |

|---|---|---|

| Mechanical boiler ash removal 2./3.train | 0.2 t/h | 8 m |

| Mechanical boiler ash removal 4. pass | 0.3 t/h | 20 m |

| Mechanical electric filter ash removal | 0.7 t/h | 15 m |

| Pneumatic electric filter and boiler ash re-moval | 0.7 t/h | 87 m |

| Pneumatic fabric filter ash removal GF1 | 0.75 t/h | 81 m |

| Pneumatic fabric filter ash removal GF2 | 0.1 t/h | 115 m |

| Bicarbonate dosing | 750 t/h | 50 m |

| Hydrated lime dosing | 50 t/h | 45 m |

| Hearth furnace coke | 7.5 t/h | 50 m |

- Boiler ash removal

- Electric filter ash removal

- Fabric filter ash removal

- Fabric filter ash recirculation

- Air distribution for air slide

- Bicarbonate dosing including injection

- Hydrated lime and hearth furnace coke dosing including injection

- Silo system

| Bulk Material | Grain size | Moisture content | Bulk density | Temperature | Property |

|---|---|---|---|---|---|

| Boiler ash 2./3. pass | fine to coarse | < 0.2 % | 0.25 t/m³ | 650 °C | abrasive |

| Boiler ash 4. pass | fine to coarse | < 0.2 % | 0.4 t/m³ | 400 °C | abrasive |

| Electric filter ash | fine | < 0.2 % | 0.4 t/m³ | 200 °C | abrasive |

| Bicarbonate | fine | - | 0.6 t/m³ | 220 – 240 °C | not abrasive |

| Hydrated lime | very fine | - | 0.6 t/m³ | 220 – 240 °C | not abrasive |

| Hearth furnace coke | very fine | < 0.5 % | 0.55 t/m³ | 20 °C | not abrasive |

Discharge chain conveyors are installed at bunker outlet points or directly in boiler hoppers. The dimensioning and construction of the large inlet opening require detailed knowledge.

The one-sided sealing turn slide valve has been especially designed for pneumatic conveying as part of the STAG pressure conveying vessel technology. No other system can satisfy the high demands of this application.

We are happy to carry out the necessary revision of replaced machine components. Send us your aggregate to Maienfeld and we will inspect and revise it. Experienced mechanics and plant and apparatus engineers inspect the unit.