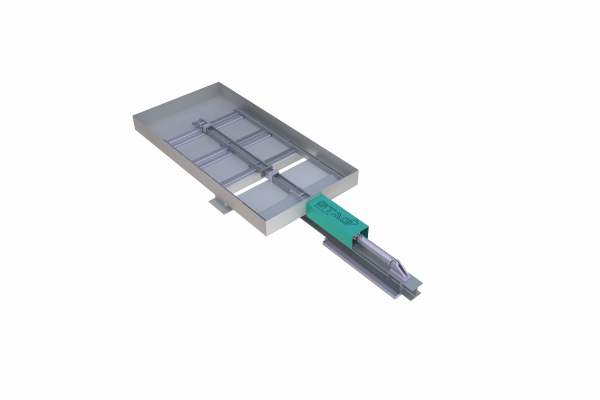

Discharge chain conveyors are installed at bunker outlet points or directly in boiler hoppers. The dimensioning and construction of the large inlet opening require detailed knowledge.

Chain conveyor are continuous conveyors and are suited for the conveyance of bulk products of all kind up to small-sized products and sludges. The advantages are its excellent temperature resistance (up to 800°C), the low conveying velocities, particularly in case of abrasive bulk material, and the robust and dustproof design.

Experience

• > 40 discharge chain conveyors built

• > 20 pcs. in the temperature range over 600°C

• 5 pcs. special design with overhead discharge

Special Characteristics – Application (USP)

• Automatic thermal expansion compensation thanks to chain slack construction

• Integrated tensioning station for wear compensation

• Low-wear design in the high-temperature range

• Exterior dustproof and pressure-resistant flange bearings

• STAG Service Support

Industries

• Waste-to-energy power plants, thermal waste treatment

• Cement industry, mineral and constructions materials

• Waste water, sewage sludge and recycling

• Steel industry

• Numerous customized solutions

- Conveying distances 6 - 20 m

- Conveying rates 1 - 100 m³/h

- Dimensions (width) 290 bis 1100 mm

- Temperature resistance up to 800°C

- The push floor is particularly well suited for poor flowing bulk products or even pasty substances such as sewage sludge.

New legal requirements, specific customer requirements or the need to modernize the system are just a few preconditions for which it is worthwile to contact STAG Service. All over decades built up experience in plant construction are at your disposal.

On behalf of Arge Transco Sedrun, STAG engineered, built and successfully commissioned, in 2003, an extraordinary transhipment plant for bulk products such as cements, ashes and microsilica necessary for the construction of the world’s longest railway tunnel.