In Istanbul, Turkey, the biggest waste-to-energy plant in Europe is being constructed.

For the three furnace lines, Hitachi Zosen Inova in Zurich opted for technologies made by STAG in order to realise the slag transport, ash removal of boilers and fabric filters as well as the absorbent handling.

The generated slag is transported into the slag bunker via a vibration slide featuring a coarse particle separator, a FE separator and a covered conveyor belt equipped with a drip pan.

The ash removal of the boilers and fabric filters are provided with well-proven mechanical and pneumatic conveying systems and impact mills of STAG.

The trough chain conveyors are fabricated in Istanbul on the basis of STAG’s design drawings, leading to savings in transport and production.

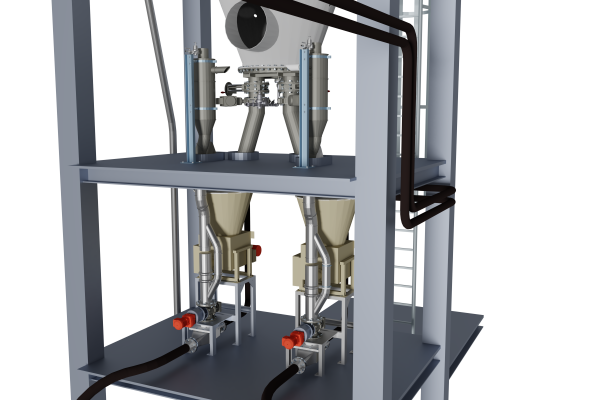

Active charcoal and hydrated lime are recirculated and injected into flue gas cleaning by means of gravimetric dosing units and continuous dilute phase conveying.

Applied Main Components

• Trough chain conveyor

• Impact mill

• Pressure conveying vessel

• Conveying line

• Butterfly valve

• Vibration slide

• Conveyor belt

• Magnetic separator

Particularities

• The configuration of the active charcoal dosing system conforms to the ATEX guidelines.

Client

• Hitachi Zosen Inova, Zürich, Switzerland

| Systems | Conveying rate | Conveying distance |

|---|---|---|

| Slag discharge | 9.2 t/h | 90 m |

| Mech./pneum. boiler ash removal | 1.2 t/h | 130 m |

| Mech./pneum. fabric filter ash removal | 3.4 t/h | 130 m |

| Active charcoal dosing | 4 - 20 kg/h | 10 m |

| Hydrated lime dosing | 100 – 1‘000 kg/h | 55 - 140 m |

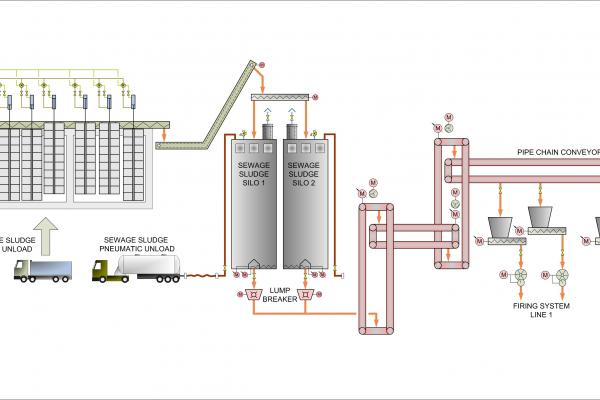

- Discharge and transport of slag including FE separation

- Boiler ash removal mechanical and pneumatic

- Fabric filter ash removal mechanical and pneumatic

- Pneumatic conveyance of powdered active charcoal

- Pneumatic conveyance of hydrated lime

| Bulk Material | Grain size | Moisture content | Bulk density | Temperature | Property |

|---|---|---|---|---|---|

| Slag | - | - | 0.5 t/m3 | 100 °C | abrasive |

| Boiler ash | - | - | 0.6 – 0.8 t/m3 | 300 °C | abrasive |

| Fabric filter ash | very fine | - | 0.6 t/m3 | 200 °C | not abrasive |

| Active charcoal | 10 – 250 µm | - | 0.5 t/m3 | ambient | not abrasive |

| Hydrated lime Ca(OH)22 | 5. 90 % < 90 µm | > 95 % | 0.45 t/m3 | ambient | not abrasive |

STAG has gained an extensive experience with the gravimetric dosing system. The system contains the dosing, the pneumatic conveying with product-specific air blast injector nozzle as well as the necessary air treatment.

Steinmüller Babcock Environment, based in Gummersbach, is realising the construction of the new waste-to-energy power plant in San Sebastian, Spain.

New legal requirements, specific customer requirements or the need to modernize the system are just a few preconditions for which it is worthwile to contact STAG Service. All over decades built up experience in plant construction are at your disposal.