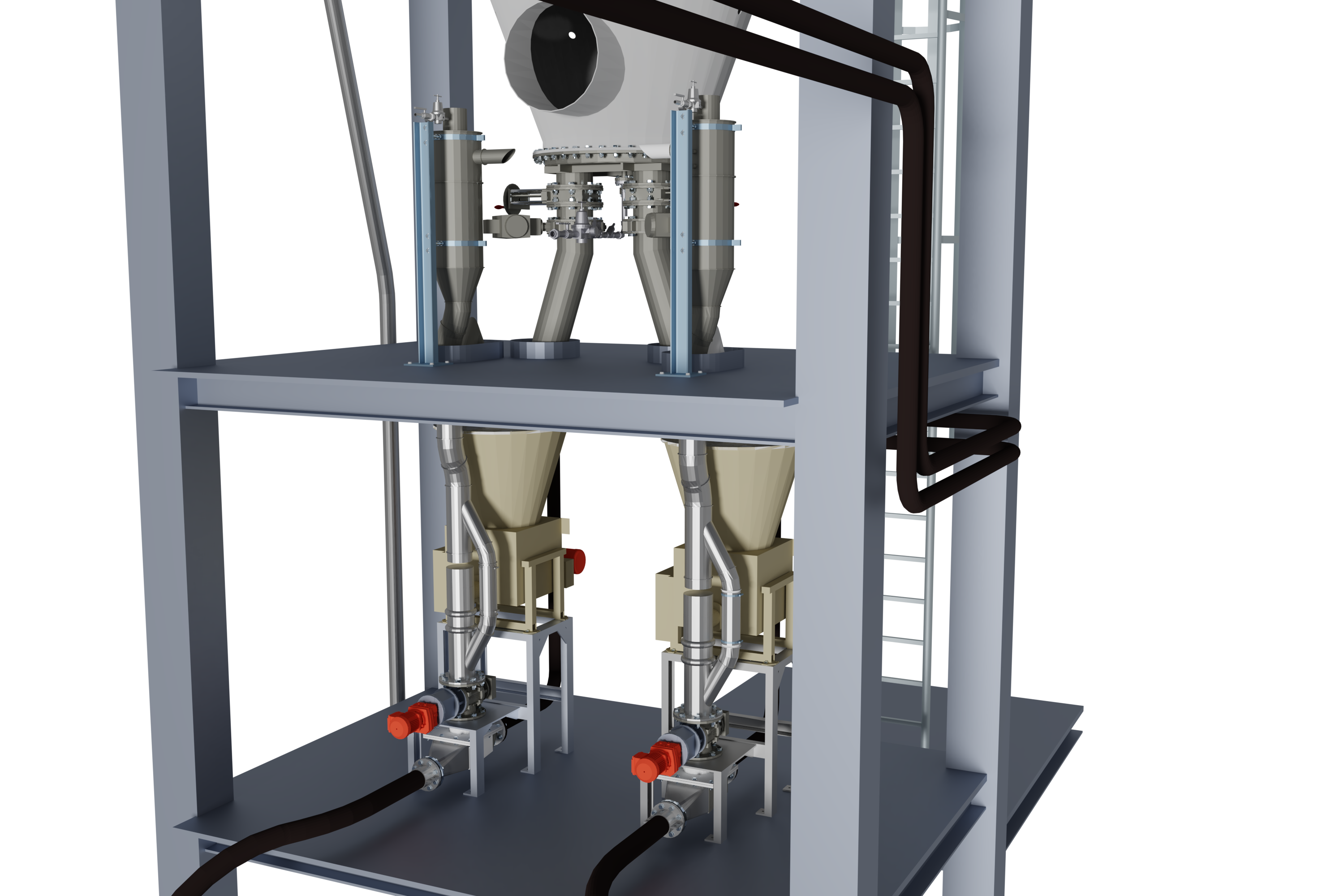

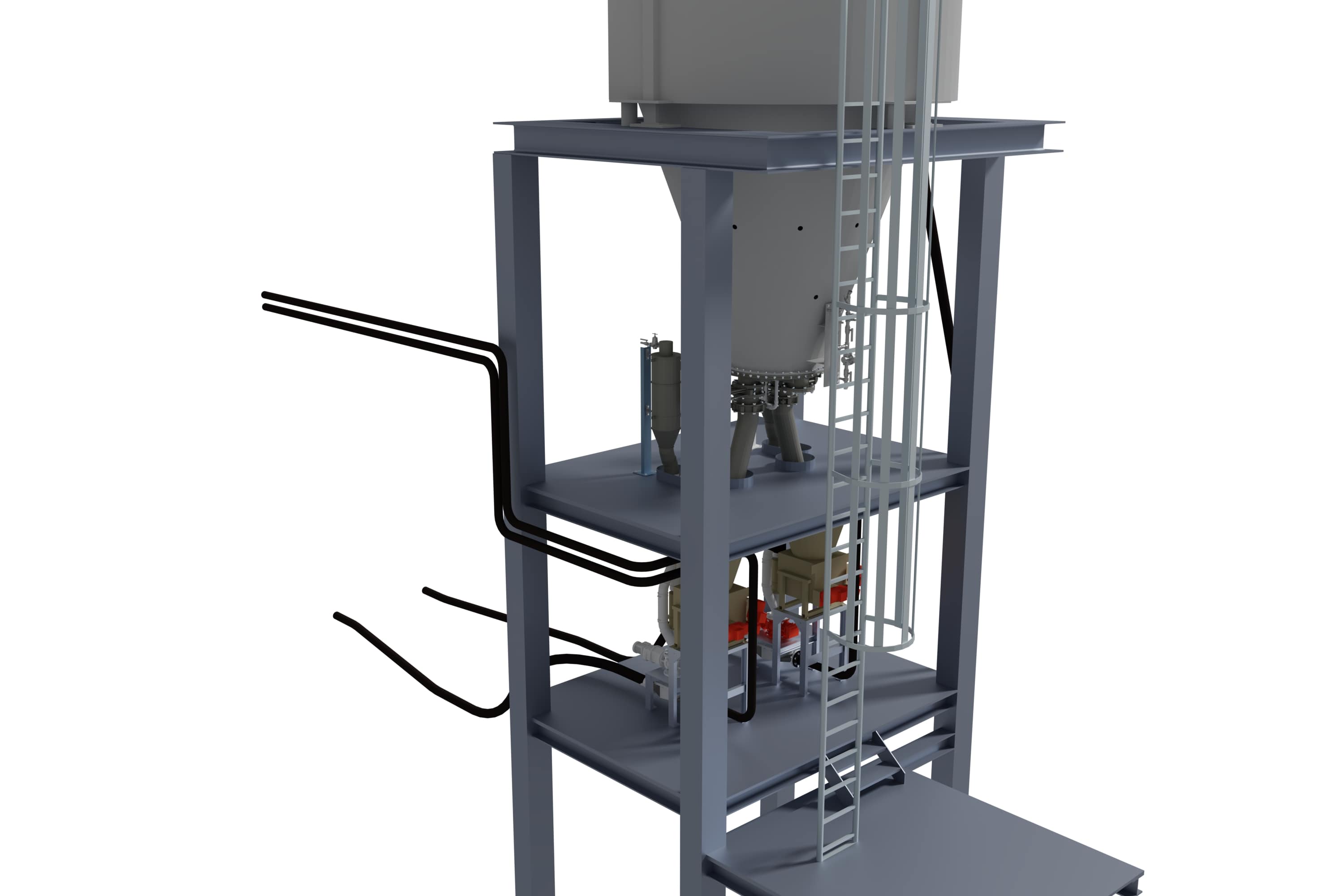

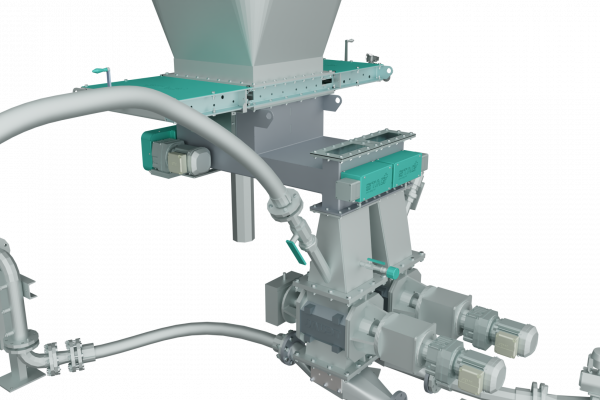

STAG has gained an extensive experience with the gravimetric dosing system. The system contains the dosing, the pneumatic conveying with product-specific air blast injector nozzle as well as the necessary air treatment. By the gravimetric or dosing principle the dosing material is being weighed by the integrated load cells. The only measurement is therefore the weight. This is carried out by a differential feed scale which is selected by individual customer requirements.

Experience

- more than 30 years of experience with this system

- > 20 installed volumetric dosing systems

Special features – applications (USP’s)

- one contact person for the entire system

- product specific air blast injector nozzle-geometrics

- ATEX compliant design

- STAG service support

Sectors

- Waste to Energy

- Power plants

- Steel plants

- Construction materials industry

- Paper industry

- etc.

At the site of Jura Cement in Wildegg, STAG has already implemented several conveying, silo and dosing projects for various bulk products.

Each year, around 100 service assignments are carried out by STAG. From small inspections up to several-weeks of a total plant revision, our customers have Projektmanager, audit managers and audit teams at their disposal. The life-cycle-oriented service backup serves as the basis. This includes t

STAG has gained an extensive experience with the volumetric dosing system. The system contains the dosing, the pneumatic conveying with product-specific air blast injector nozzle as well as the necessary air treatment.