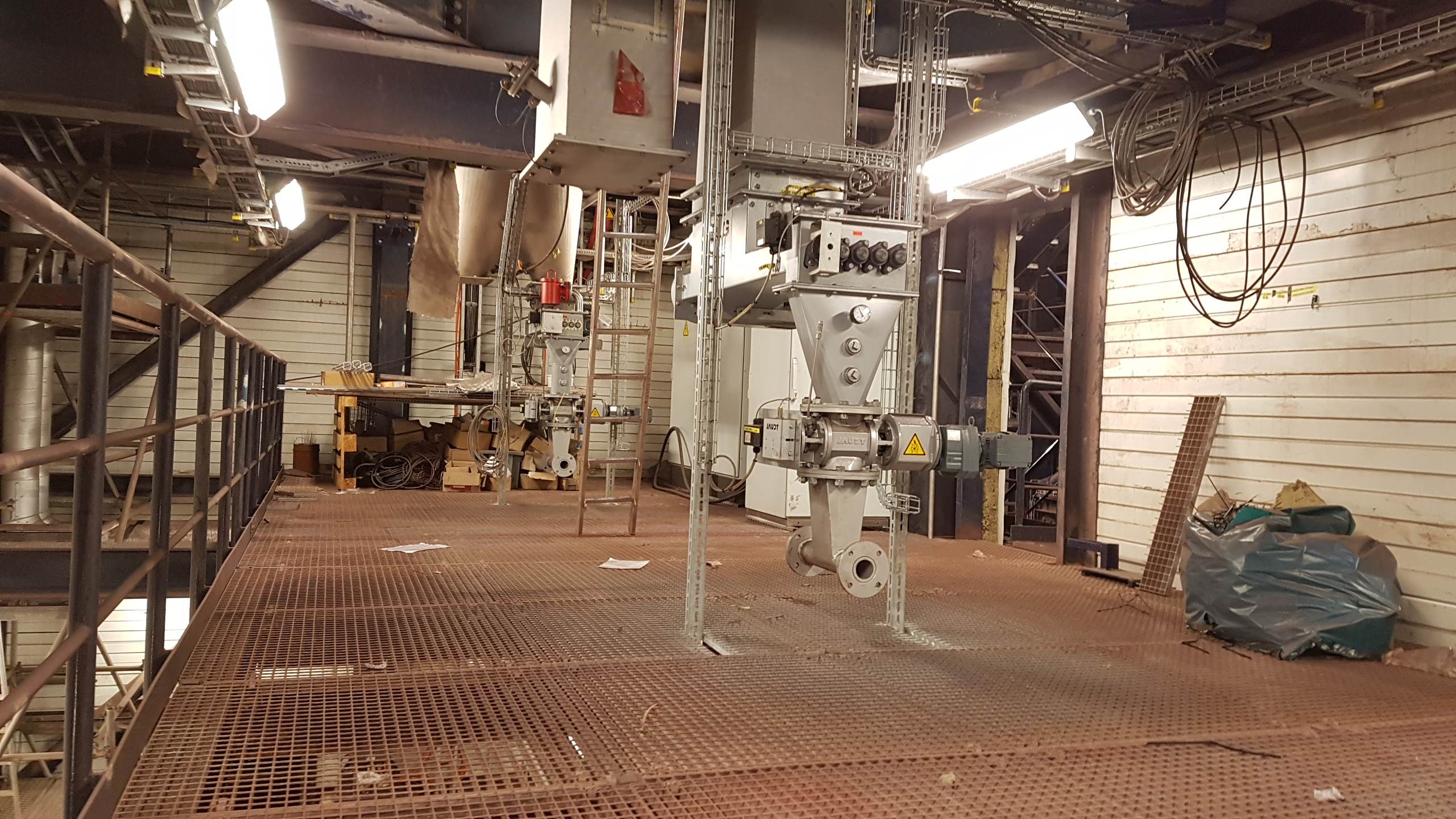

At its location in Duisburg-Huckingen, Germany, the Hüttenwerke Krupp Mannesmann GmbH (HKM) runs an integrated iron and steelworks.

As the general contractor, the Steinmüller Babcock Environment GmbH was in charge of the construction of a new fabric filter for ash removal purposes from the sintering plant. The configuration of this plant is a process gas cleaning facility by means of bicarbonate (NaHCO3) and hearth furnace coke (HOK).

As a long standing supplier, STAG was entrusted in 2018 with the provision of a pneumatic conveying system for the transport of the reaction products (residues) separated in the fabric filter, into the recirculation intermediate silo or the residue silos.

The adsorbents required for the separation of toxic substances are discharged from the fresh adsorbent silos by means of volumetric dosing units, and subsequently injected – prior to the fabric filter - into the flue gas channel using a butterfly valve and the pneumatic dilute phase conveying method.

Residue recirculation / discharge and conveying:

• Stop valve

• Compensator

• Two-way diverter

• Collector tank

• Rotary vane feeder

• Butterfly valves

• Ventilation station conveying air dilute phase conveying

• Conveying lines

Recirculation emergency discharge:

• Stop valve

• Rotary vane feeder

• Loading facility

Adsorbent dosing flue gas cleaning

• Volumetric dosing unit

• Rotary vane feeders

• Butterfly valves

• Conveying lines dilute phase

• Ventilation station conveying air dilute phase conveying

Particularities

- The plant has been engineered, built and put into operation according to the current requirements stipulated in ATEX Directive 2014/34/EU.

Client

- Steinmüller Babcock Environment GmbH

| Systems | Conveying rate | Conveying distance |

|---|---|---|

| Dosing hearth furnace coke HOK | 10 - 100 kg/h | - |

| Dosing hydrated lime CaCO3 | 60 - 600 kg/h | - |

| HOK / CaCO3 | 0.07 - 0.7 t/h | 67 m |

| Residues | 4x 5.3 t/h | 78 - 96 m |

- Mechanical and pneumatic transport of residual substances into the residue silos

- Adsorbent dosing systems including dilute phase conveying

| Bulk material | Grain size | Moisture content | Bulk density | Temperature | Property |

|---|---|---|---|---|---|

| Hearth furnace coke HOK | 100 %< 0.1mm | trocken | 0.4 - 0.6 t/m³ | 40°C | little abrasive, explo-sive |

| Hydrated lime (CaCO3) | 100 %< 0.1mm | trocken | 1.0 t/m³ | 40°C | not abrasive |

| Residues | 100 %< 0.1mm | trocken | 0.4 - 0.8 t/m³ | 150°C | little abrasive |

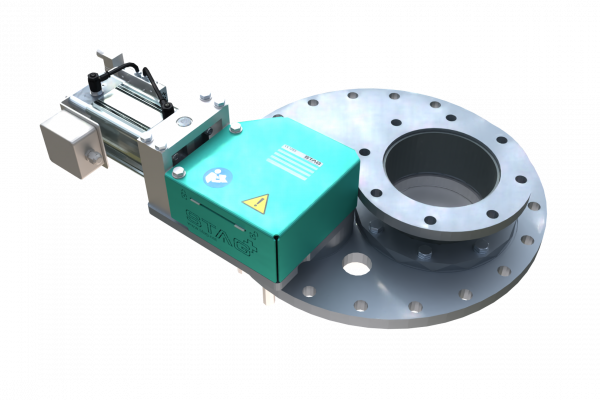

The one-sided sealing turn slide valve has been especially designed for pneumatic conveying as part of the STAG pressure conveying vessel technology. No other system can satisfy the high demands of this application.

Based on our long and successful partnership with HAMON RESEARCH-COTTRELL and ArcelorMittal, we are periodically entrusted with the supply of ash removal plants and additive dosing systems.

Each year STAG handles around 500 customer orders and achieves satisfied customers around the world. Here too, the focus lies on life-cycle-oriented warehousing as well as the plant availability. The experienced employees of the business area service are happy to answer any questions or suggestio