At the premises of Holcim (Süddeutschland) GmbH, STAG has implemented several projects concerning pneumatic and mechanical conveying, silo and dosing systems for different bulk products such as cement, iron oxide, hydrated lime, iron(II) sulphate, furnace dust, granulated slag, paper ash and broken oil shale.

The use of roofing felt as alternative fuel resulted in a fascinating project. Trucks deliver the cut roofing felt as well as chips of tyres, wood and plastics, which are then automatically transferred and fed onto two dosing units and discharge conveyors by means of an overhead crane. A subsequent conveying belt serves for evacuating the roofing belt.

Applied Main Components

• Bicarbonate/hydrated lime silo including fluidisation system

• Screw conveyors

• Rotary vane feeders

• Pneumatic dilute phase conveying with butterfly valve

• Bicarbonate mill

• Pressure conveying vessel

• Conveying lines

• Silo vehicle loading station

• Mixing screw for moistening of residues

Particularities

• Moistening of flue ash and residues

Client

• Veolia Water System s.p.z.o.o.

| Systems | Conveying rate | Conveying distance |

|---|---|---|

| Hydrated lime dosing | 20 - 200 kg/h | 25 m |

| Bicarbonate dosing | 5 - 100 kg/h | - |

| Roofing felt dosing | 0.5 - 7.0 t/h | - |

| Iron-ll pressure conveying vessel transport to dosing unit | 4.5 t/h | bis 290 m |

| Iron(II) dosing (per dosing unit) | 0.12 - 0.9 t/h | - |

| Granulated slag pressure conveying vessel transport in intermediate silo | 70 / 15 t/h | 100 m |

| Oil shale transport to silo | 120 t/h | - |

| Oil shale dosing Charge into fluidised bed furnace | 18 t/h | - |

| Paper ash dosing | 1.2 - 3.75 t/h | 100 m |

- • Hydrated lime and bicarbonate dosing

• Oil shale dosing incl. pneum. dilute phase conveying

• Alternative fuel dosing system (roofing felt/wood/plastic and tyre chips)

• Iron(II) sulphate pneum. pressure conveying vessel transport to silo

• Iron(II) sulphate dosing systems

• Pneumatic conveying system for flue ash transport (paper ash)

• Pneumatic conveying system for granulated slag transport

| Bulk material | Grain size | Moisture content | Bulk density | Temperature | Property |

|---|---|---|---|---|---|

| Granulated blast furnace slag | 3700 Blain | < 0.2 % | 1.0 t/m³ | 20 °C | abrasive |

| Iron(II) sulphate | 99.9 % < 1‘000 µm | dry | 0.8 t/m³ | 20 °C | not abrasive |

| Hydrated lime | < 0.1 mm | dry | 0.42 t/m³ | 20 °C | not abrasive |

| Bicarbonate | < 0.5 mm | dry | 0.8 - 1.3 t/m³ | 20 °C | not abrasive |

| Oil shale | 0 - 12mm | 4 - 7 % | 1.25 t/m³ | 20 °C | not abrasive |

| Paper ash (flue ash) | 100 % < 200 µm | dry | 0.4 t/m³ | 20 °C | abrasive |

| Roofing felt | < 50 mm | 5 – 10 % | 0.4 - 0.8 t/m³ | 20 °C | Sticky under higher temperatures |

| Tyre chips | 0 - 200 mm | 5 – 10 % | 0.45 t/m³ | 20 °C | abrasive |

| Wood chips | 0 - 200 mm | 5 – 10 % | 0.3 t/m³ | 20 °C | abrasive |

| Plastic chips | 0 - 200 mm | 5 – 10 % | 0.15 t/m³ | 20 °C | abrasive |

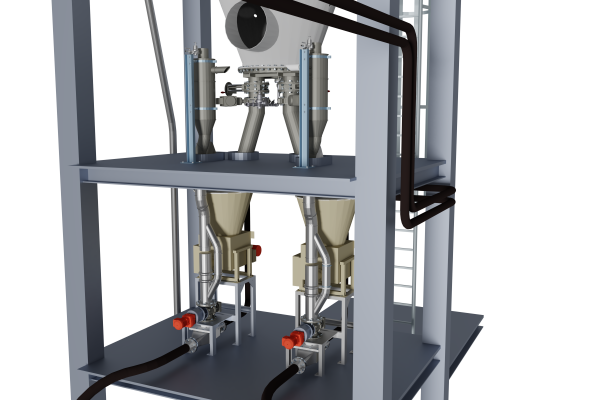

STAG has gained an extensive experience with the gravimetric dosing system. The system contains the dosing, the pneumatic conveying with product-specific air blast injector nozzle as well as the necessary air treatment.

New legal requirements, specific customer requirements or the need to modernize the system are just a few preconditions for which it is worthwile to contact STAG Service. All over decades built up experience in plant construction are at your disposal.

During their long-year partnership, Holcim (Schweiz) AG and STAG have already implemented most various conveying systems for bulk products all over Europe.