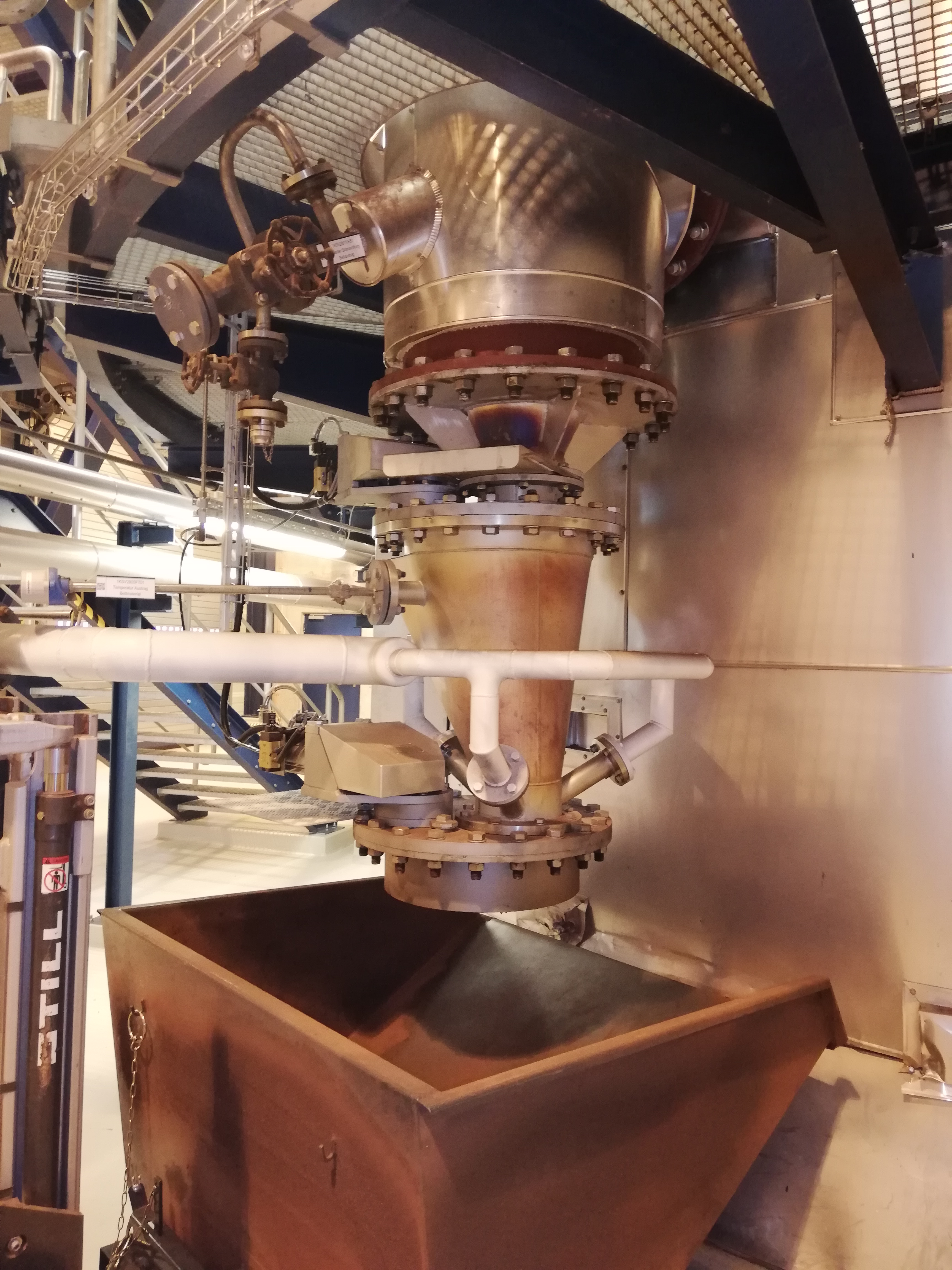

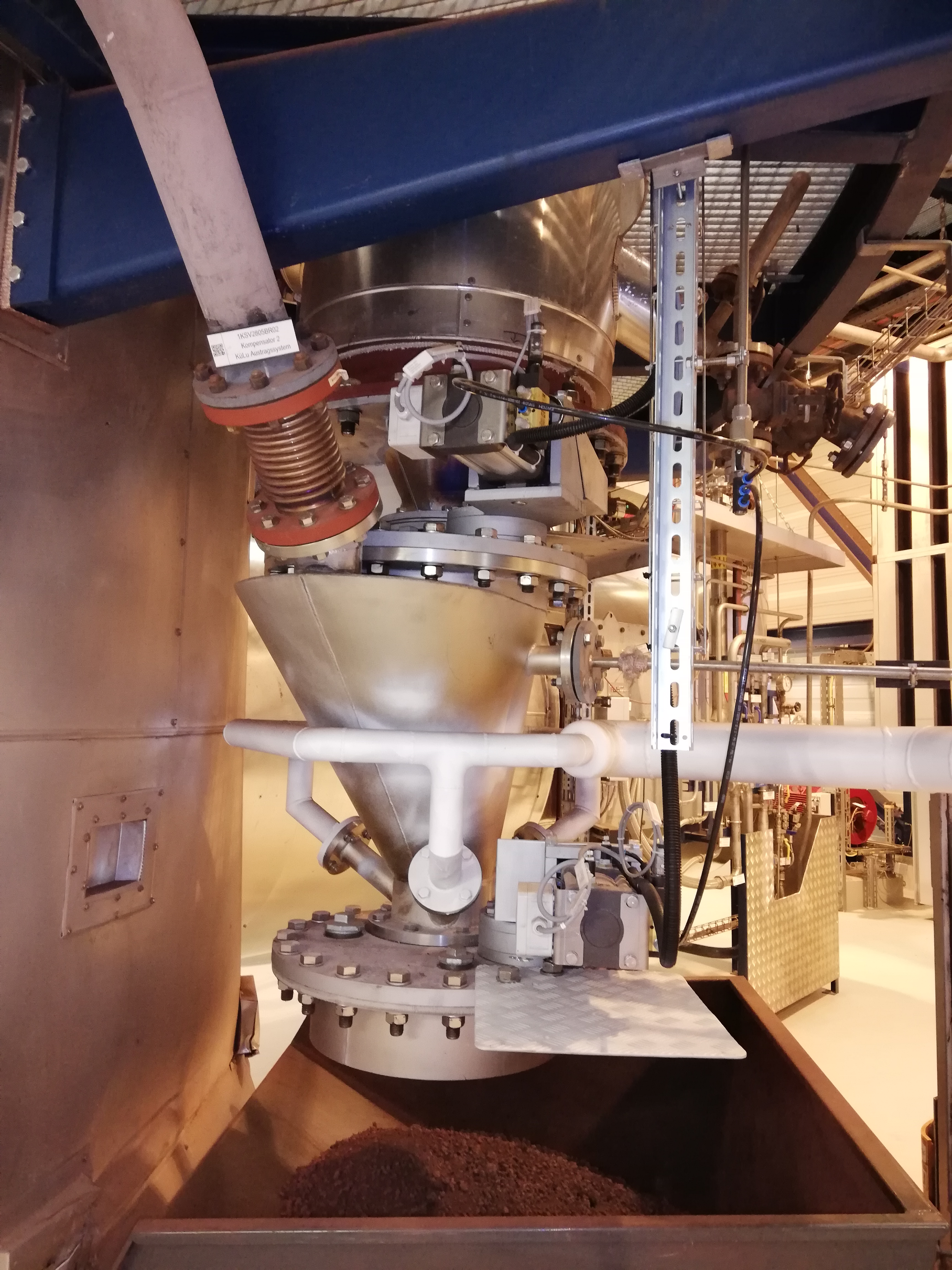

The STAG discharge and dosing module is realized with two bulk material slides and an intermediate container. The dimensioning of the intermediate tank makes the application areas very versatile and easy to modify.

For a discharge of hot bed ash from a fluidized bed furnace, the intermediate tank was supplemented with air cooling. This option prolongs the service life of the bulk material slide valves at temperatures up to 800°C.

Experiences:

- Approx. 850 Rotary valves on pressure end vessels (to DGRL)

- approx. 20 rotary valves in the sluice function

Special Features - Applications (USP's):

- short-term temperature resistance up to 800°C

- Functional reliability thanks to special design

- Simple replacement of wearing parts

- Low overall height

- Long service life

- Metal sealing

Branches

- Power plants of all kinds

- Cement works

- Steel plants

- Mixed plaster production

- a.m.m.

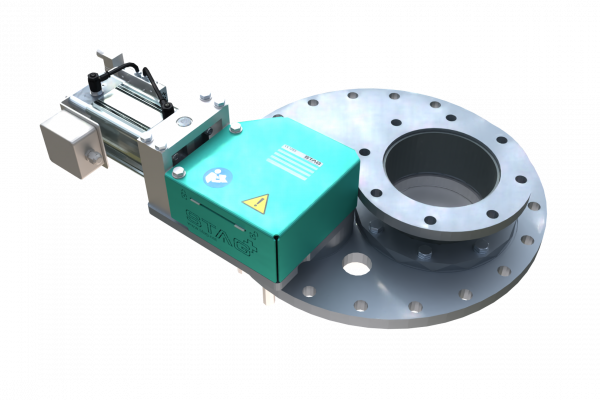

The one-sided sealing turn slide valve has been especially designed for pneumatic conveying as part of the STAG pressure conveying vessel technology. No other system can satisfy the high demands of this application.

Each year, around 100 service assignments are carried out by STAG. From small inspections up to several-weeks of a total plant revision, our customers have Projektmanager, audit managers and audit teams at their disposal. The life-cycle-oriented service backup serves as the basis. This includes t

In this diesel-fired power plant, exhaust air is cleaned by means of two electric filters. Respectively two trough chain conveyors per filter serve for evacuating the ash. For each line, a collecting trough chain conveyor is provided receiving the ash.