For a steel works in Ostrava (CZ), STAG was awarded the contract to engineer, produce and supply a conveying and injection system for hearth furnace coke (HOK) and limestone (CaCO3) for the purpose of separating dioxides from the flue gases.

Both additive compounds are pneumatically fed into the silos via a silo vehicle unloading pipe.

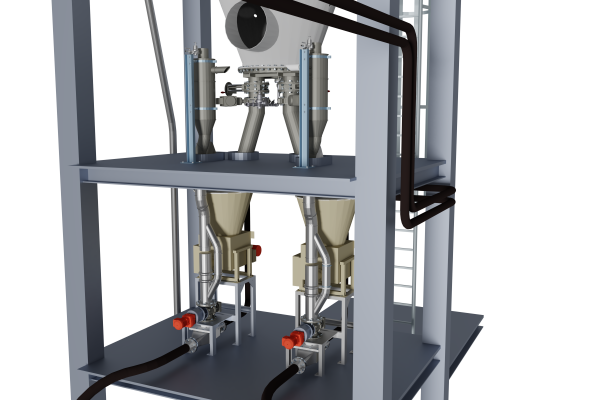

The discharge from the silos is ensured by means of gravimetric dosing units and subsequent butterfly valve conveyance to the injection points located in the flue gas channels.

In order to conform to the requirements of explosion protection, limestone is added to the hearth furnace coke at the inerting stage.

The additive compounds, also called residues, are discharged from the fabric filter by means of a screw conveyor provided by the customer and fed into a collector tank followed by a pneumatic conveyor line.

The residue silo is provided with an emptying facility used for the filling of silo vehicles.

Applied Main Components

Adsorbents

• Silo equipment hearth furnace coke/hydrated lime silo

• Gravimetric differential dosing units

• Rotary vane feeders

• Butterfly valves

• Conveying air treatment (ventilation block)

• Dilute phase conveying line

• Injection lances into flue gas channel

Residue conveyance form fabric filter

• Collector tank

• Pressure conveying vessel

• Dense phase conveying line

• Residue silo equipment

Residue loading

• Pneumatic and mechanical silo discharge facility (fluidisation / Silex / compressed air cannons)

• Rotary vane feeder

• Loading unit with filter system

Particularities

• The plant has been designed, built and put into operation according to the current requirements stipulated in the ATEX Directive 2014/34/EU.

• For explosion protection purposes, the system always conveys a mixture of limestone meal and active charcoal.

Client

• Paul Wurth GmbH

| Systems | Conveying rate | Conveying distance |

|---|---|---|

| Hearth furnace coke dosing (HOK) | 30 - 60 kg/h | - |

| Limestone meal dosing (CaCO3) | 100 - 200 kg/h | - |

| Pneumatic CaCO3- / HOK-transport into flue gas channel | 0.1 - 0.3 t/h | Linie 4 = 50 m / Linie 5 = 50 m |

| Pneumatic residue transport from fabric filter into residue silo (CaCO3 / HOK) | 0.6 t/h | 90 m |

| Silo vehicle loading Residues | 49 t/h | - |

Adsorbents

- Gravimetric dosing system

- Pneumatic conveying system (dilute phase)

- Inertisation system Hearth furnace coke (HOK)

Residue conveying from fabric filter

- Pneumatic conveying system (dense phase)

Residue loading

- Pneumatic / mechanical silo discharge system

- Silo vehicle loading system

| Schüttgut | Grain size | Moisture content | Bulk density | Temperature | Property |

|---|---|---|---|---|---|

| Limestone meal (CaCO3) | 95 % < 90 µm | < 0.2 % | 0.9 t/m3 | Umgebung | not abrasive |

| Hearth furnace coke (HOK) | 80 % < 63 µm | < 0.5 % | 0.5 t/m3 | Umgebung | abrasive |

| Residues from fabric filter (metallic oxide dust) | 95 % < 90 µm | < 0.2 % | 0.8 t/m3 | 80 - 160 °C | slightly abrasive |

STAG has gained an extensive experience with the gravimetric dosing system. The system contains the dosing, the pneumatic conveying with product-specific air blast injector nozzle as well as the necessary air treatment.

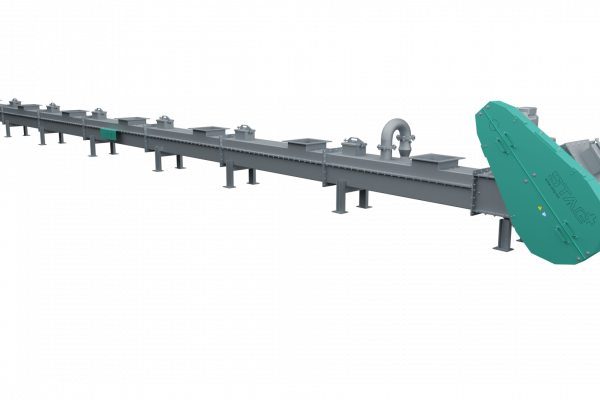

Chain conveyor are continuous conveyors and are suited for the conveyance of bulk products of all kind up to small-sized products and sludges.

Each year STAG handles around 500 customer orders and achieves satisfied customers around the world. Here too, the focus lies on life-cycle-oriented warehousing as well as the plant availability. The experienced employees of the business area service are happy to answer any questions or suggestio