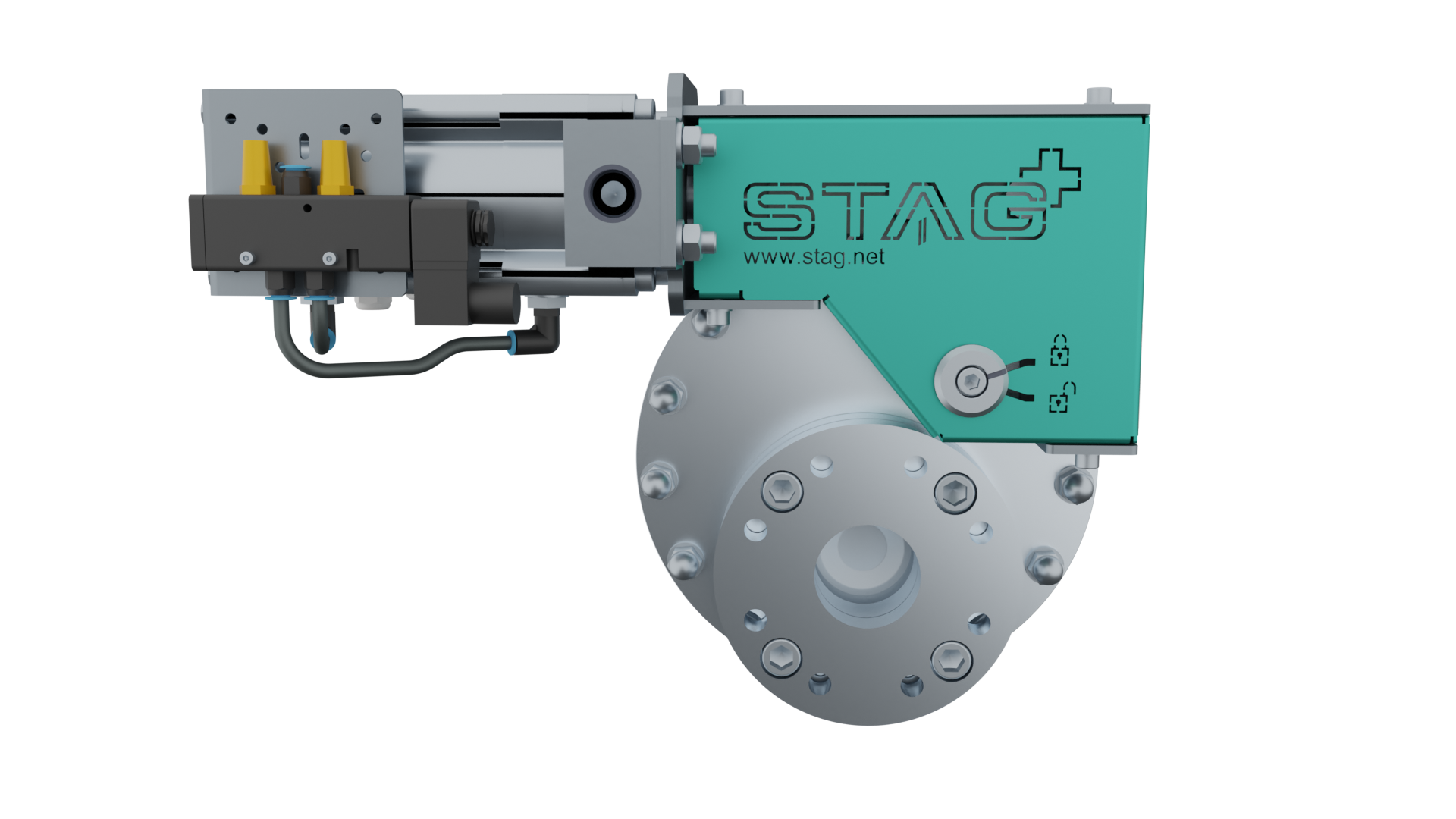

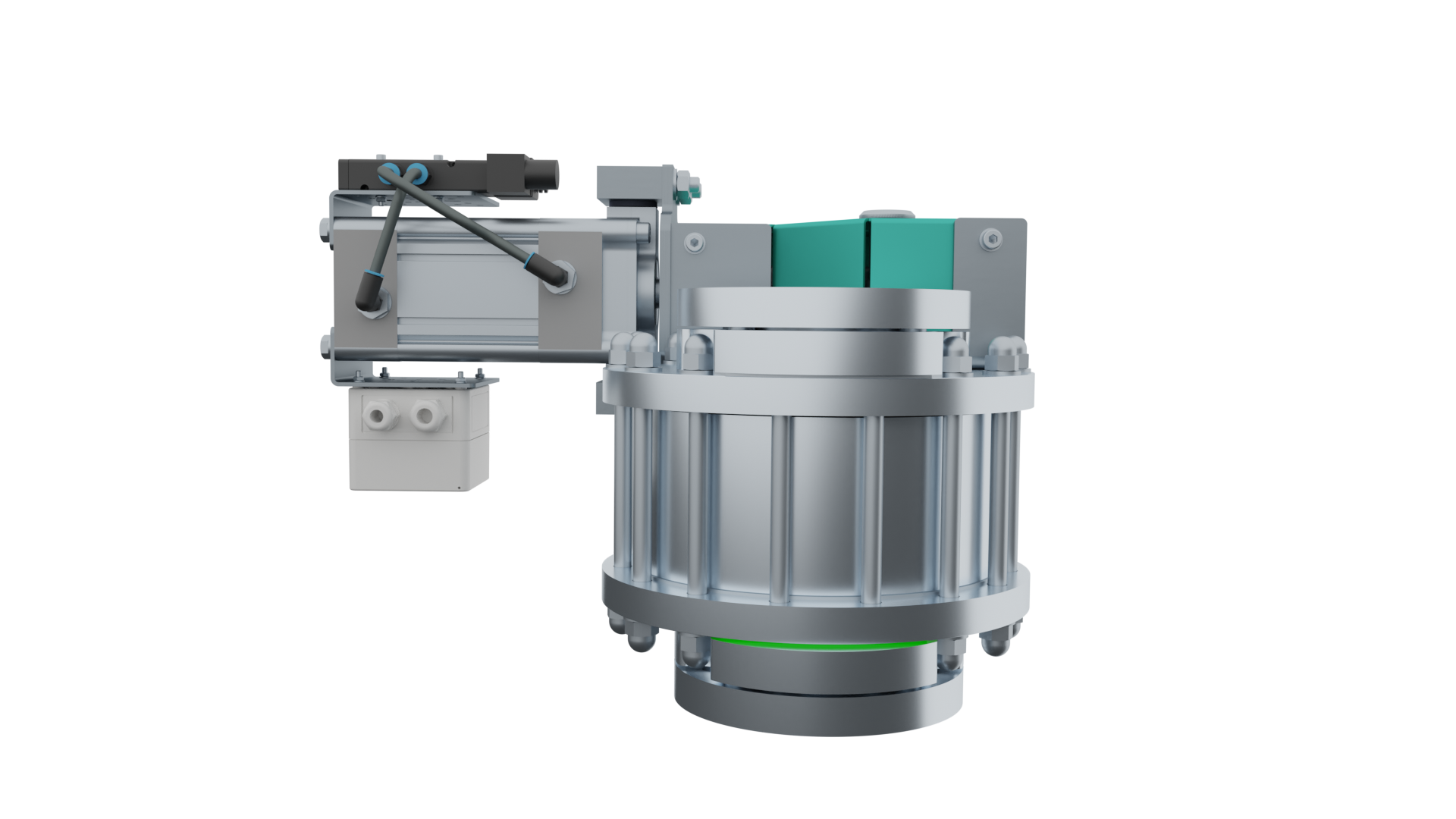

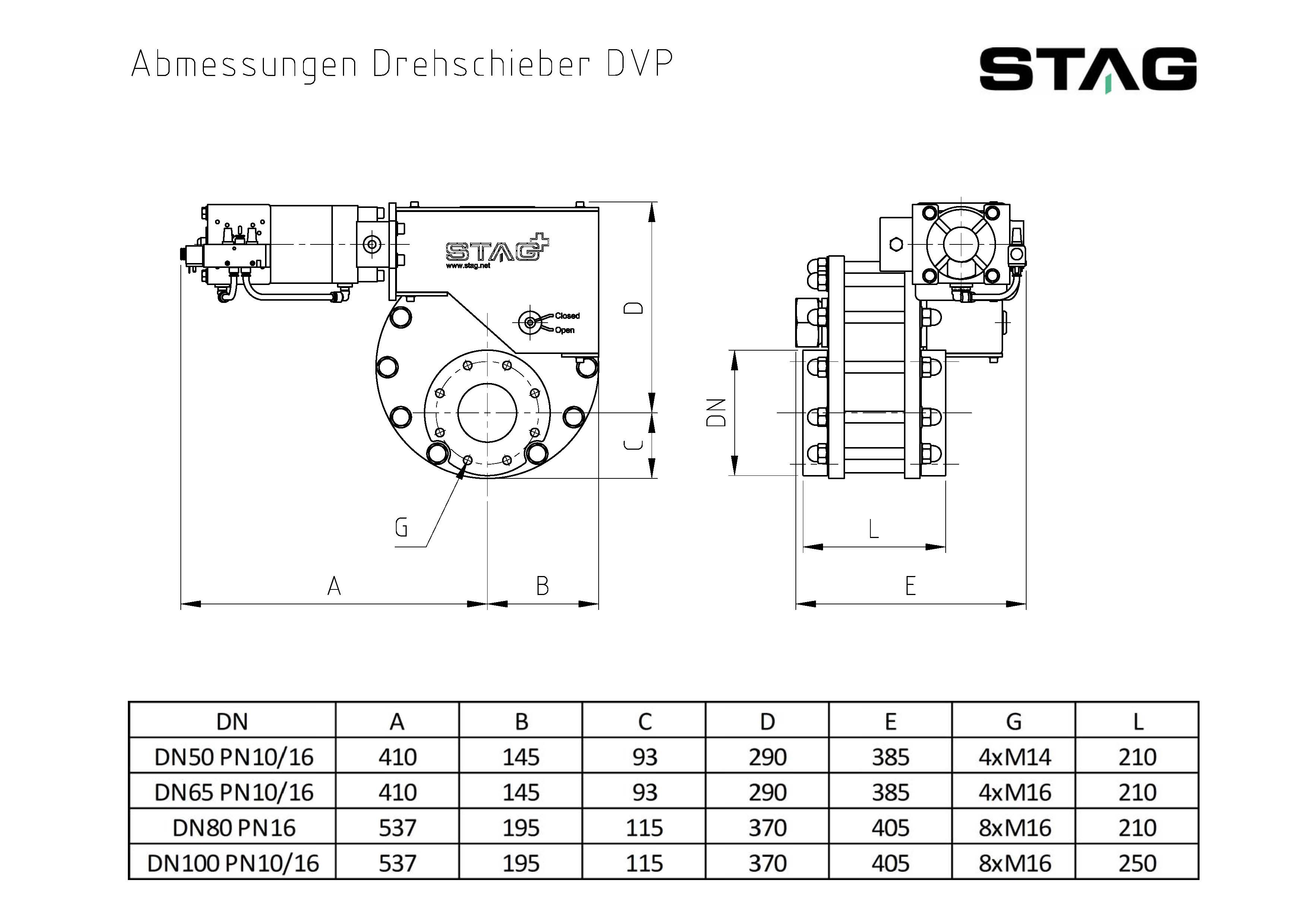

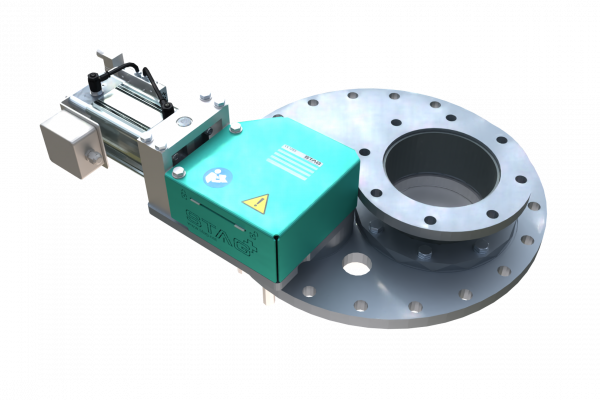

The double-sided sealing turn slide valve has been especially designed for pneumatic conveying as part of the STAG pressure conveying vessel technology. No other system can satisfy the high demands of this application. The turn slide valve, suitable for pressure conveying vessels as well as for any kind of bulk material, is a pressure-proof outlet device ensuring the system’s long-term functionality.

More than 750 devices of its preceding model (turn slide valve MVP) valves are successfully operated throughout the world. Resistant to wear and to temperatures up to 400°C, the device has successfully proven in practice. A special patent provides for its long-term functional capability and tightness of this high-tech valve.

Experiences

Special Characteristics – Application (USP)

- No compression stress due to swivel drive

- Low-wear construction

- High functional safety due to special construction

Industries

- Power stations of all kinds

- Cement plants

- Steel plants

- Production of mixed plaster

- etc.

- Pressure-tight up to 6 bar(ü)

- Closing and opening time < 1 sec.

A special mechanism generates a rotary movement of the slide plates when the valve is opened or closed. The metallic sealing surfaces are always in contact to each other irrespective of the valve’s position, thus protecting the metallic sealing surfaces against punctual wear whereas, at the same time, tightness rises with the increasing number of cycles. The sharp-edged slide plates remove any deposits on the sealing surfaces.

The one-sided sealing turn slide valve has been especially designed for pneumatic conveying as part of the STAG pressure conveying vessel technology. No other system can satisfy the high demands of this application.

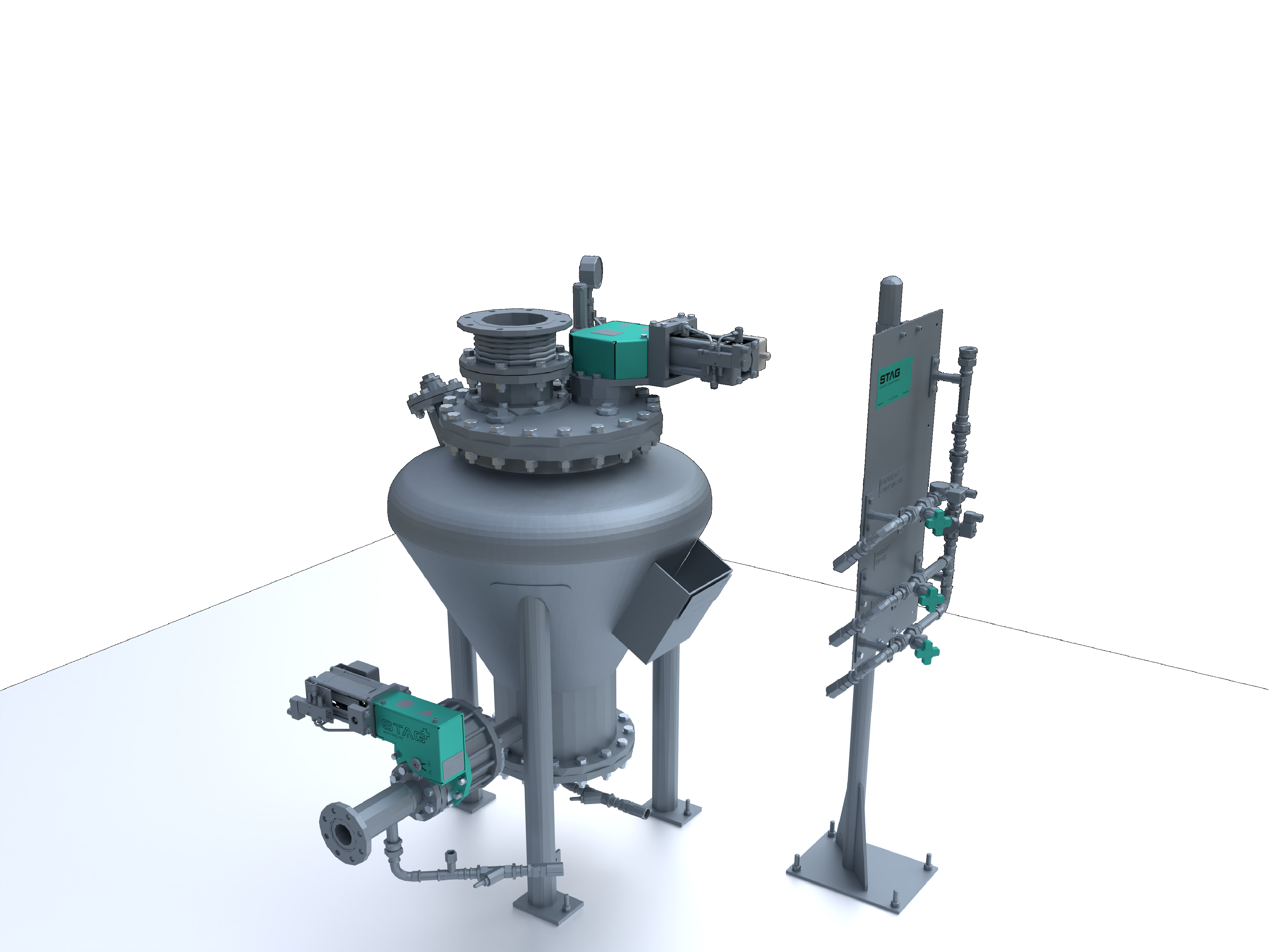

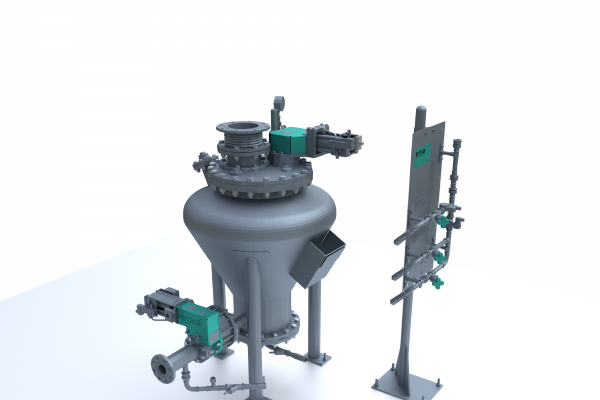

The pressure conveying vessel is used by STAG when it comes to challenging tasks, high conveying rates and long con-veying distances. This pneumatic conveying application using the dense flow method combines energy-optimised conveying processes with perfect operational safety.

In the waste-to-energy power plant Hagenholz, the overall bulk material handling in the area of boiler and flue gas cleaning, ash washing as well as dry slagging has been installed by STAG.