STAG uses bulk material-specific designs for fluidisation.

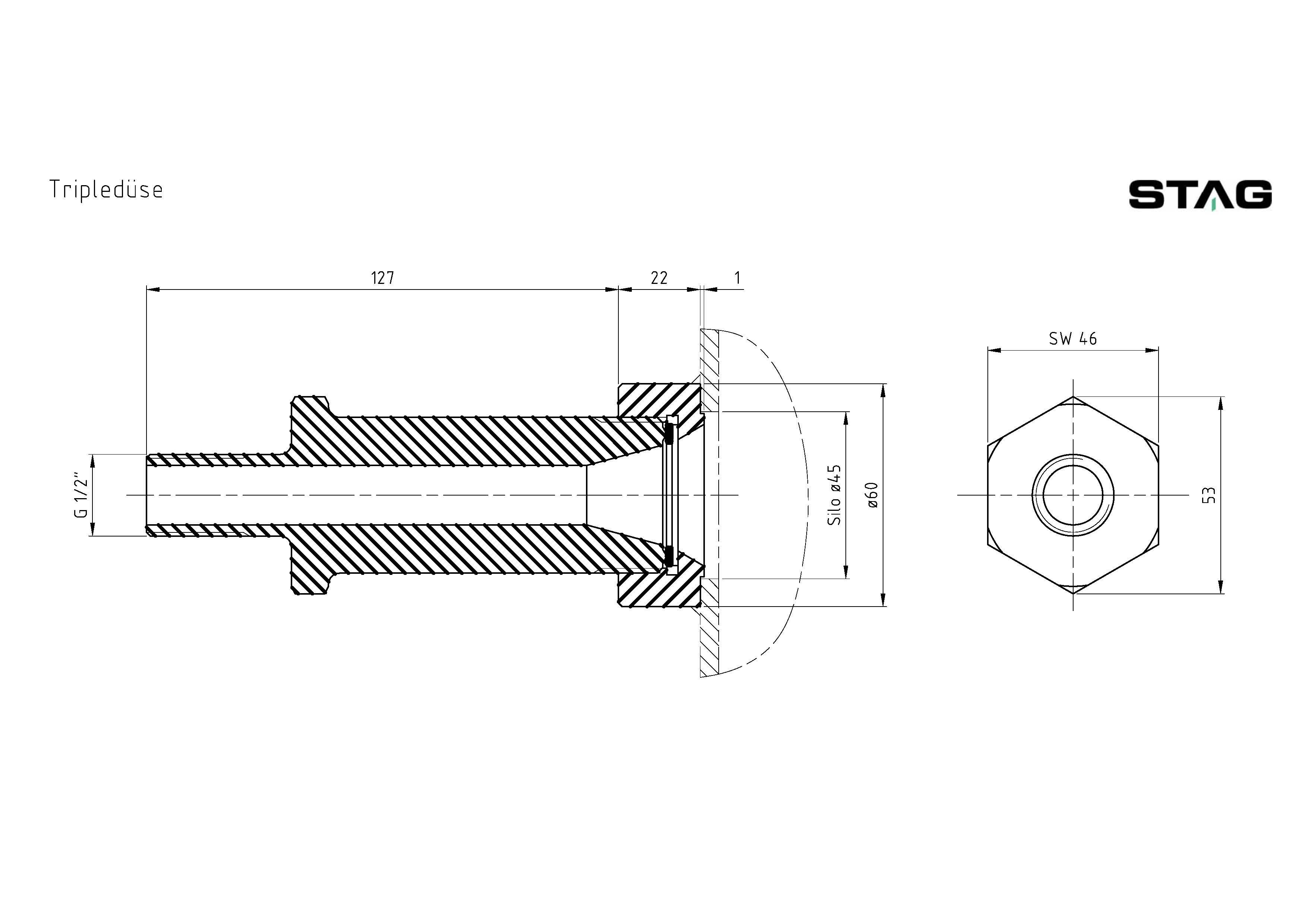

Tripple Nozzles are used as a discharge aid for bulk materials in containers, silos and downpipes.

The special nozzle shape achieves a high degree of loosening. They are particularly suitable for fine powders (average particle size approx. 20–500 μm) that are easy to fluidize, such as cement. Valve nozzles are particularly suitable for very fine powders (average particle size approx. < 20 μm) that are difficult to fluidize.

USPs

- Easy to assemble, simple installation

- Can be retrofitted to existing systems with little effort

- Accessible from the outside (assembly/disassembly/service/maintenance)

- Great effect with low air consumption

- Operating pressure 2–6 bar (g)

- Temperature-resistant for bulk materials up to 200°

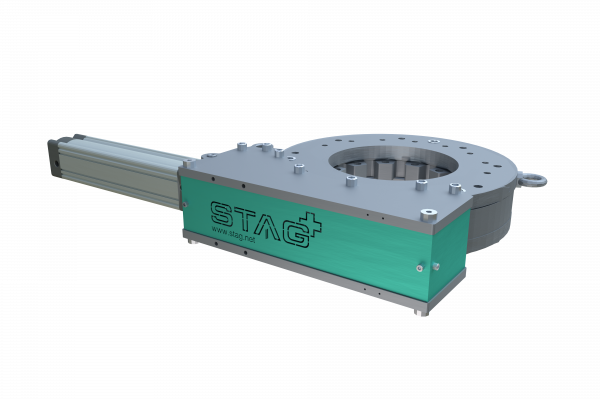

The mechanical discharge aid „Silex“ is used for conveying poor flowing and not fluidizable bulk products. It is incorporated into round or angular-shaped silos, bunkers and containers.

In Gelsenkirchen, BP is running refinery and petrochemical plants in the city districts Horst and Scholven.

As a specialist company, STAG has been entrusted to supply the conveying systems and components ensuring the removal of catalyst dust of the newly built FCC plant.

Each year, around 100 service assignments are carried out by STAG. From small inspections up to several-weeks of a total plant revision, our customers have Projektmanager, audit managers and audit teams at their disposal. The life-cycle-oriented service backup serves as the basis. This includes t