In 2014, a new waste-to-energy power plant equipped with two lines was built in Vantaa, Finland. The two general contractors for boilers and flue gas cleaning opted for conveying technology made by STAG. Thereby, the 10th plant fitted with STAG systems and components on Scandinavian soil was launched.

STAG mounted the standard combination composed of a mechanical conveying system using a trough chain conveyor, a treatment facility based on the impact mill and the subsequent pneumatic conveying facility using a pressure conveying vessel. STAG was furthermore entrusted the engineering and delivery of the slag handling system.

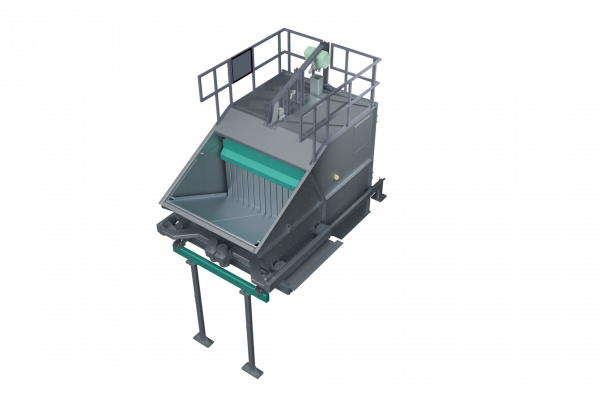

Two coarse particle separators presenting an integrated two-way deflector convey the slag, after the ram slag extractor, to two redundant conveyor belts. These conveyor belts are covered over their entire length with an extraction hood and are provided with a drip pan at certain critical points.

Applied Main Components

• Coarse sieve separator including deflector

• Conveyor belts

• Trough chain conveyor

• Impact mill

• Pressure conveying vessel

Particularities

• Slag handling with coarse sieve separator

Client

• Hitachi Zosen Inova

• LAB Groupe CNIM

• Vantaan Energia Oy

| Systems | Conveying rate | Conveying distance |

|---|---|---|

| Slag handling | 12 t/h | 50 m |

| Boiler ash removal 2./3. pass | 1.0 t/h | 15 m |

| Boiler ash removal horizontal pass | 2.0 t/h | 90 m |

| Electric filter ash removal | 2.0 t/h | 90 m |

| Fabric filter ash removal | 4 x 2.0 t/h | 60 m |

- Slag discharge

- Mechanical and pneumatic boiler and electric filter ash removal

- Fabric filter ash removal

| Bulk material | Grain size | Moisture content | Bulk density | Temperature | Property |

|---|---|---|---|---|---|

| Boiler ash 2./3. passg | Fine with lumps | - | 0.25 t/m³ | 650 °C | abrasive |

| Boiler ash removal horizontal pass | fine to coarse | - | 0.4 t/m³ | 400 °C | abrasive |

| Elektrofilter-Asche | fine | - | 0.4 t/m³ | 200 °C | abrasive |

| Residues from fabric filter | very fine | dry | 0.5 t/m³ | 150 °C | abrasive |

In Istanbul, Turkey, the biggest waste-to-energy plant in Europe is being constructed.

Coarse particle separators are used in mechanical conveying processes of bulk products in order to eliminate larger particles (impurities). The benefits are an improved operational safety of the conveying system, which can be reduced in size after the coarse particle separator.

We are happy to carry out the necessary revision of replaced machine components. Send us your aggregate to Maienfeld and we will inspect and revise it. Experienced mechanics and plant and apparatus engineers inspect the unit.