In 2008, the most southern waste-to-energy power in plant in Switzerland has been put into operation. Commissioned by the three general contractors of the contract sections Boiler, Flue gas cleaning and Ash Washing, STAG supplied the conveying technology and storage sys-tems for various bulk products. STAG served as an important link and und coordinated these interfaces to the full satisfaction of all parties involved.

Since the putting into operation of the overall plant, STAG has been assisting the operating company in stock-keeping, plant optimisation and by providing annual service operations, thus ensuring an optimum operational safety and system availability.

The waste-to-energy power plant located in Giubiasco is an excellent example illustrating STAG’s LifeCycle philosophy. STAG supported the general contractors during the projecting and construction phase and afterwards, the operator by ensuring safety and availability based on service backups.

Applied Main Components

• Trough chain conveyor 2./3. train

• Trough chain conveyor boiler and electric filter ash

• Boiler and electric filter ash emergency removal

• Sieve impact mill

• Pressure conveying vessel

• Silo system

Particularities

• Since the commissioning, 2x/year service and optimisation of the overall plant.

Client

• Hitachi Zosen Inova

• Martin München

• BSH Umweltservice AG

• ACR (operator)

| Systems | Dosing rate | Conveying rate | Conveying distance |

|---|---|---|---|

| Boiler ash removal | - | 2.5 t/h | 90 m |

| Electric filter ash removal | - | 2.5 t/h | 90 m |

| Fabric filter ash removal | - | 2.0 t/h | 80 m |

| Fresh adsorbent | - | 40 t/h | 60 m |

| Fresh adsorbent | 0.2 - 2.0 t/h | - | 25 m |

| Old adsorbent | 0.05 - 0.5 t/h | - | 100 m |

- Boiler ash removal 2./3. and 4.train

- Electric filter ash removal

- Fabric filter ash removal

- Adsorbent handling

- Old adsorbent recirculation

- Hydrated lime storage and dosing

- Silo system

| Bulk material | Grain size | Moisture content | Bulk density | Temperature | Property |

|---|---|---|---|---|---|

| Boiler ash 2./3.pass | 10-200 mm | Technisch tro-cken | 0,8 t/m³ | 400 °C | abrasive |

| Fabric filter ash | very fine | < 0.5 % | 0.7 t/m³ | 150°C | - |

| Electric filter ash | very fine | < 0.5 % | 0.5 t/m³ | 180 °C | not abrasive |

| Hydrated lime | 96 %< 90 µm | <1.0% | 0.5 t/m³ | 20 °C | not abrasive |

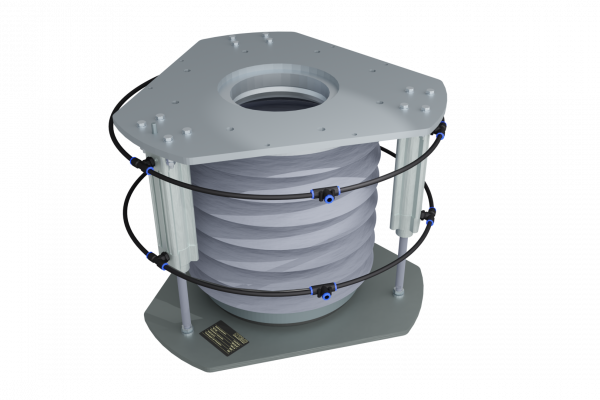

The Filling Adapter has a very wide field of application. STAG uses this system, among other things, for the emergency discharge of ash removal systems.

New legal requirements, specific customer requirements or the need to modernize the system are just a few preconditions for which it is worthwile to contact STAG Service. All over decades built up experience in plant construction are at your disposal.

In 2014, a new waste-to-energy power plant equipped with two lines was built in Vantaa, Finland. The two general contractors for boilers and flue gas cleaning opted for conveying technology made by STAG.