At the factory premises of ThyssenKrupp, Europe’s largest steel manufacturing site of an area five times as big as Monaco, STAG compo-nents and systems are mounted at different locations.

After having identified the requirements of the general contractor, STAG developed outstanding overall concepts to be applied in the dust removal of cast and sinter houses.

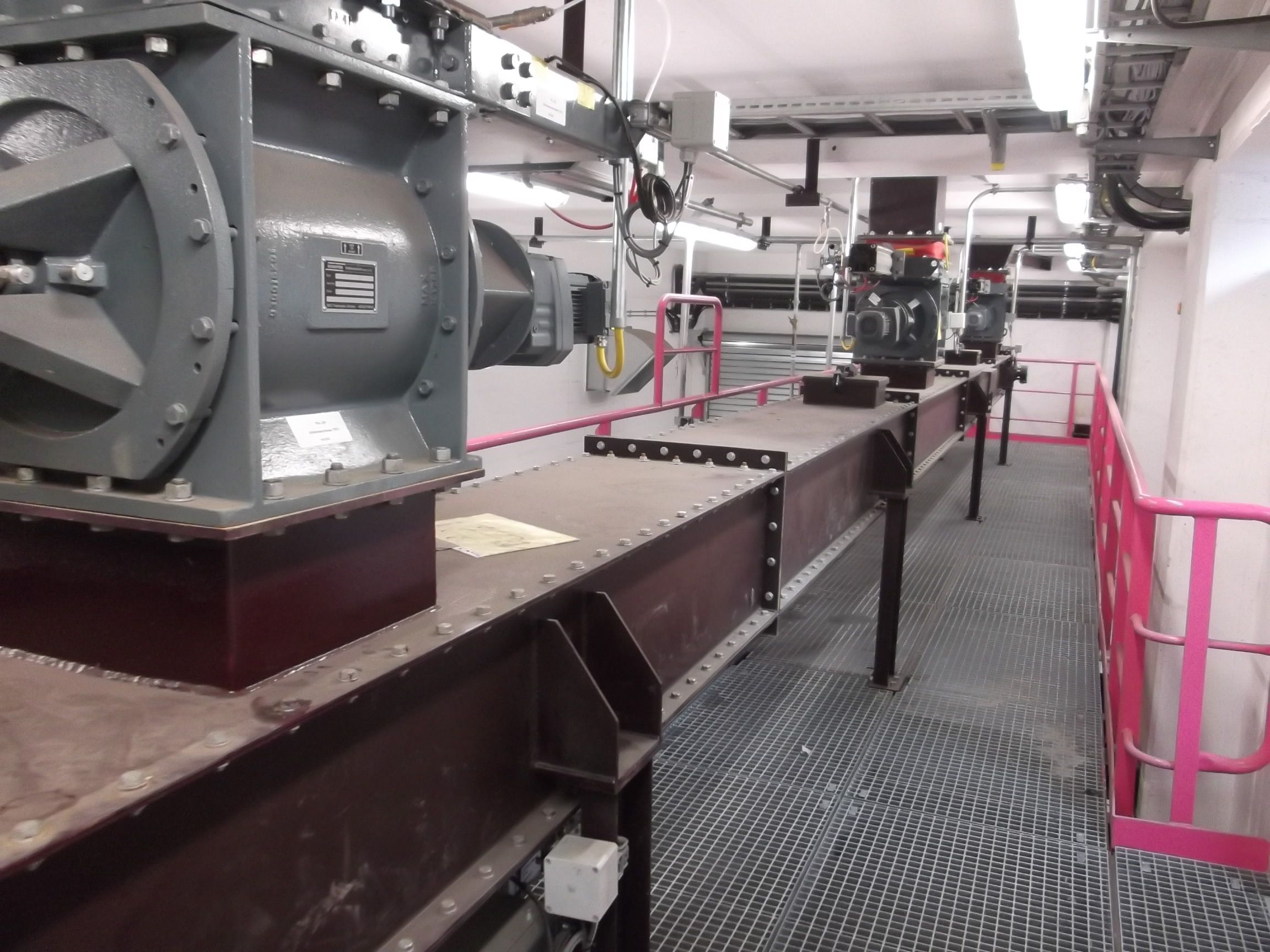

Dusts arising in the casthouses, stockhouses and underground bunkers for additive substances are separated in filter systems, discharged by means of trough chain conveyors and fed into the silos using pneumatic conveying systems.

The sinter dust generated in the sinter plant is separated in a filter system and then mechanically fed into the pneumatic conveying system. The pneumatic conveyance into an existing ash silo is ensured by means of nitrogen.

Applied Main Components

• Trough chain conveyor

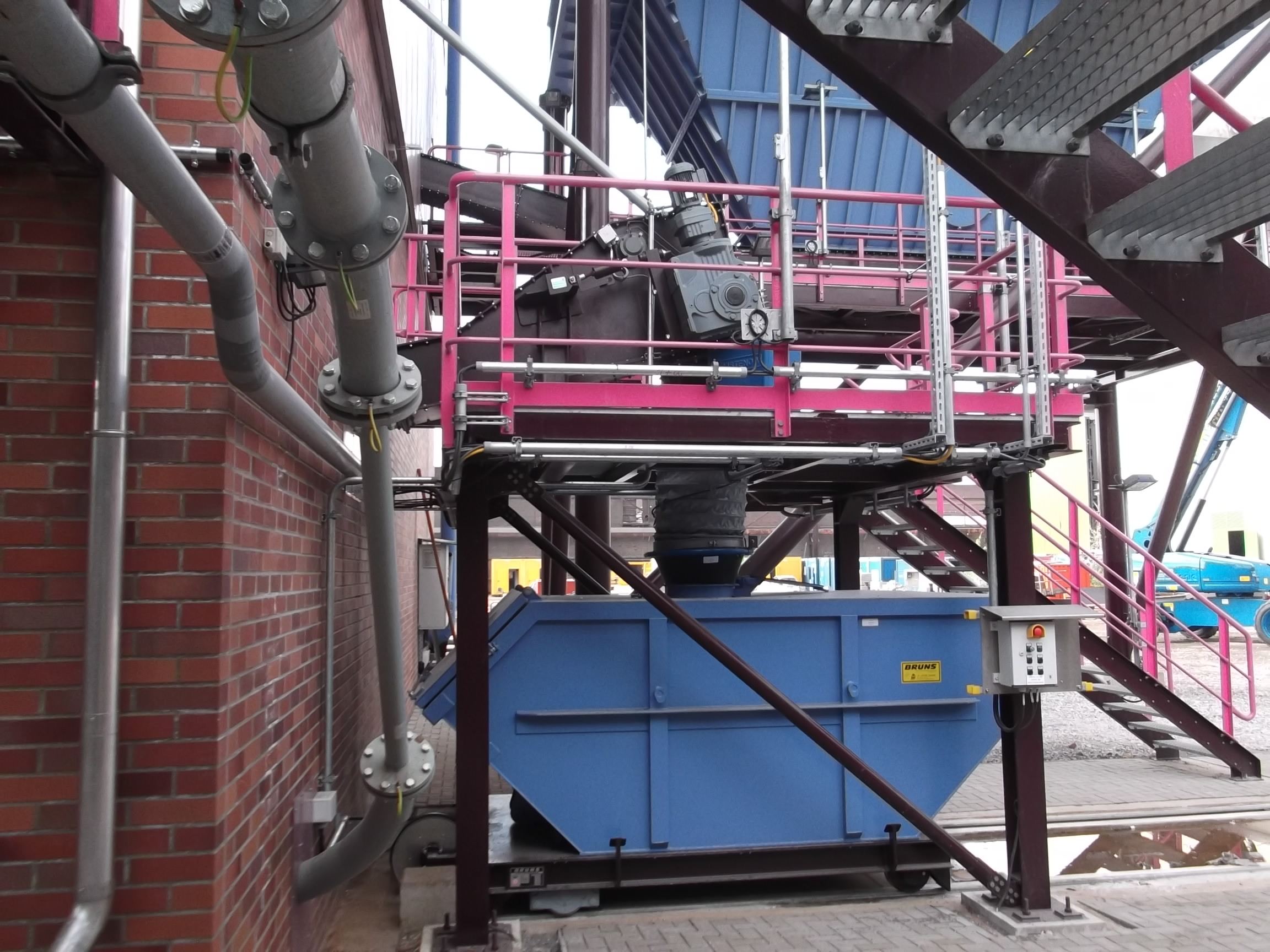

• Pressure conveying vessel

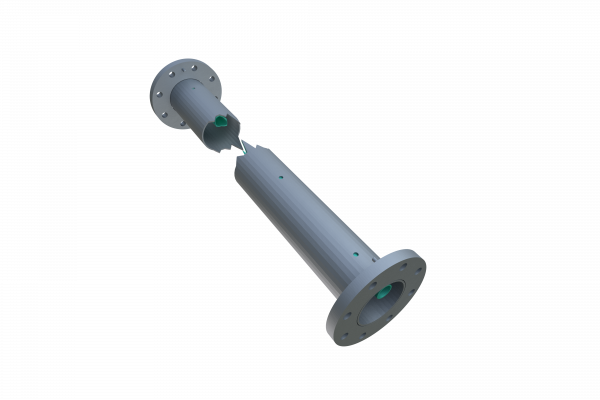

• Dense phase conveying line (Denseflow system)

• Container loading

Particularities

• In spite of very high variations in the weight of bulk products, high-level functionality and operational safety could be ensured through/by the installation of a STAG Denseflow system.

Client

• GEA Bischoff

• Balke-Dürr GmbH

• Paul Wurth

• Thyssen Krupp

| Systems | Conveying rate | Conveying distance |

|---|---|---|

| Pneum. foundry dust transport | 8.0 t/h | 200 m |

| Pneum. foundry dust transport incl. dust from stockhouse | 5.5 t/h | 270 m |

| Pneum. dust removal underground bunker (90% lime) | 0.2 t/h | 35 m |

| Pneum. sinter dust transport | 5.5 t/h | 200 m |

- Mechanical/pneumatic conveying system for stockhouse and blast furnace dust

- Pneumatic conveying system dust removal underground bunker

- Pneumatic conveying system dust removal sinter dust plant

| Bulk Material | Grain size | Moisture con-tent | Bulk density | Temperature | Property |

|---|---|---|---|---|---|

| Foundry dust | < 200 µm | trocken | 0.6–2.8 t/m³ | 45 °C | abrasive |

| Foundry dust and dust from casthouse | < 200 µm | trocken | 0.6–2.8 t/m³ | 45 °C | abrasive |

| Dust removal underground bunker (90% lime) | 95 % < 1 mm | trocken | 1.2 t/m³ | < 80 °C | not abrasive |

| Sinter dust | 95% < 0.2mm | < 0.2 % | 1.8 t/m³ | < 180 °C | abrasive |

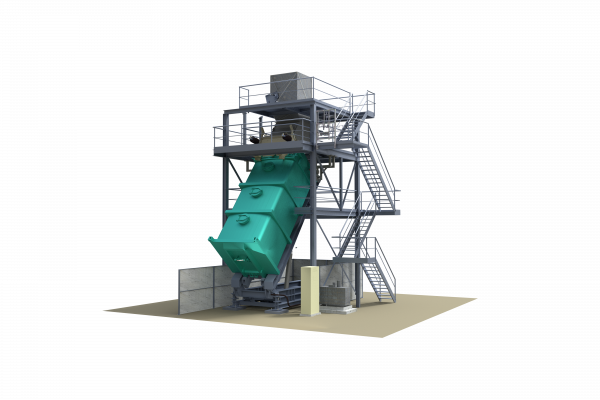

STAG’s container handling system enables automated and dust-tight filling of roll-off containers. The

container is tilted with the traversing and tilting station, thus achieving an ideal filling level.

In conventional conveyances of powdered bulk materials through smooth pipes, the irregularity of the flow rises with the increasing pipe length. This in turn, increases the wear of the system.

Each year STAG handles around 500 customer orders and achieves satisfied customers around the world. Here too, the focus lies on life-cycle-oriented warehousing as well as the plant availability. The experienced employees of the business area service are happy to answer any questions or suggestio