Following heavy fuel combustion in the refinery of Exxon Mobil, three electric filters separate the arising ash.

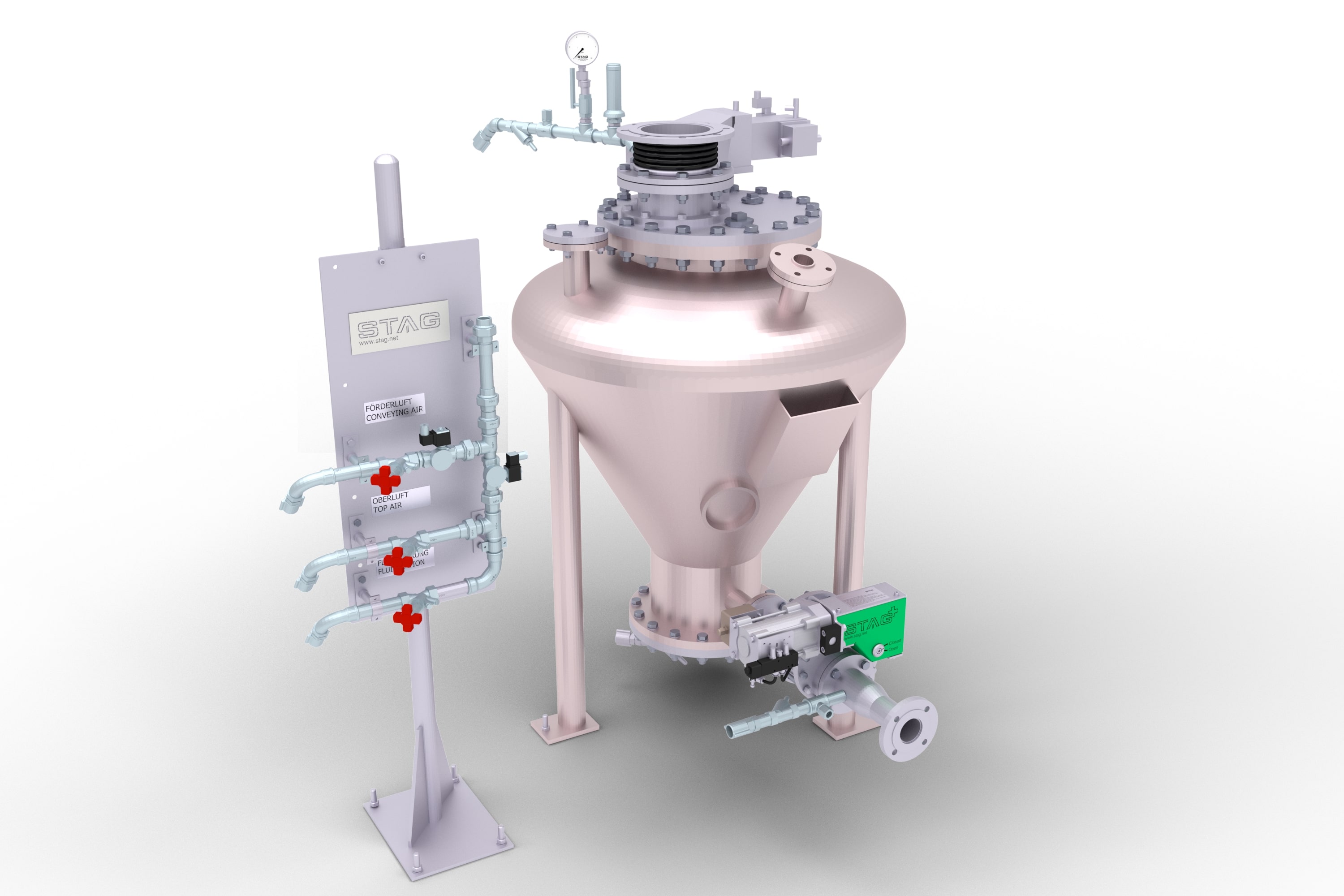

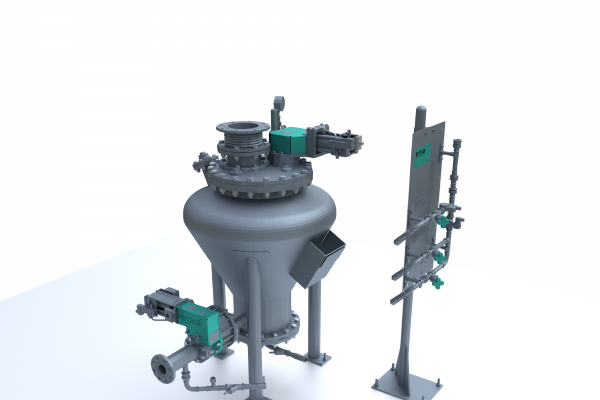

Underneath each electric filter, six pressure conveying vessels are mounted, transporting the ash via a common conveying line into a silo. Thus, conveyance of the complete ash by means of three conveying lines is ensured. STAG Triplex nozzles serve as silo discharge system. A truck loading facility fed the ash into trucks.

The configuration of the plant conforms to Exxon Mobil regulations, and the system is controlled by means of a STAG control.

Applied Main Components

- Pressure conveying vessel

- Control System

- Silo vehicle loading facility

Client

- ExxonMobil Chemical France / HAMON RESEARCH COTTRELL

- EFACEC Ambiente, S.A.

- Pneumatic electric filter ash removal

- Silo vehicle loading facility

| Bulk Material | Grain size | Moisture content | Bulk density | Temperature | Property |

|---|---|---|---|---|---|

| Electric filter ash | 95 % < 90 µm | < 0.5 % | 0.4 – 0.5t/m³ | Max. 200 °C | abrasive |

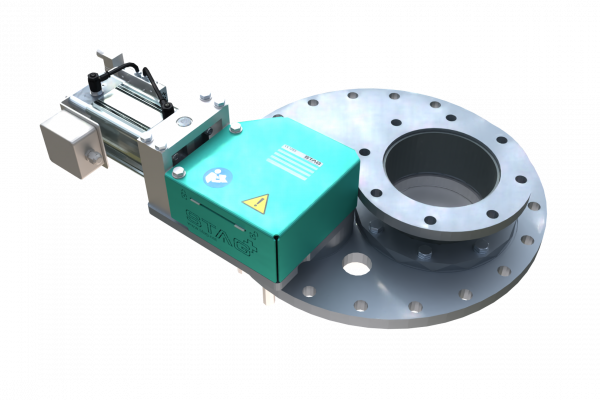

The one-sided sealing turn slide valve has been especially designed for pneumatic conveying as part of the STAG pressure conveying vessel technology. No other system can satisfy the high demands of this application.

The pressure conveying vessel is used by STAG when it comes to challenging tasks, high conveying rates and long con-veying distances. This pneumatic conveying application using the dense flow method combines energy-optimised conveying processes with perfect operational safety.

Each year STAG handles around 500 customer orders and achieves satisfied customers around the world. Here too, the focus lies on life-cycle-oriented warehousing as well as the plant availability. The experienced employees of the business area service are happy to answer any questions or suggestio