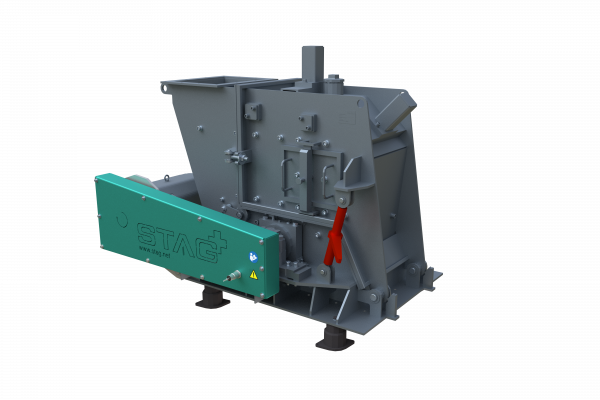

Designed for crushing lumps as well as agglomerated material within the bulk material.

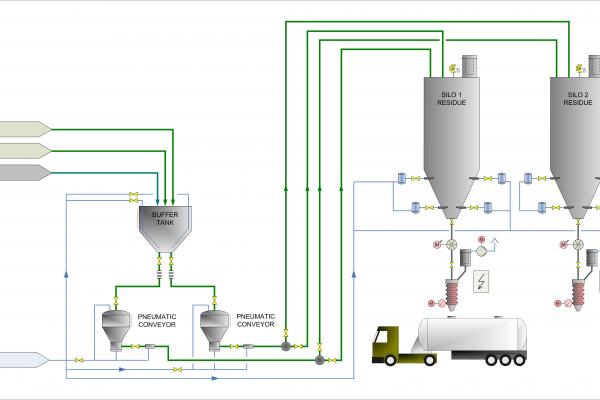

In lump breaker applications, the oversize grain is prepared for subsequent pneumatic or mechanical conveying or ensiling procedures.

Experience

- > 100 mounted lump breakers throughout the world

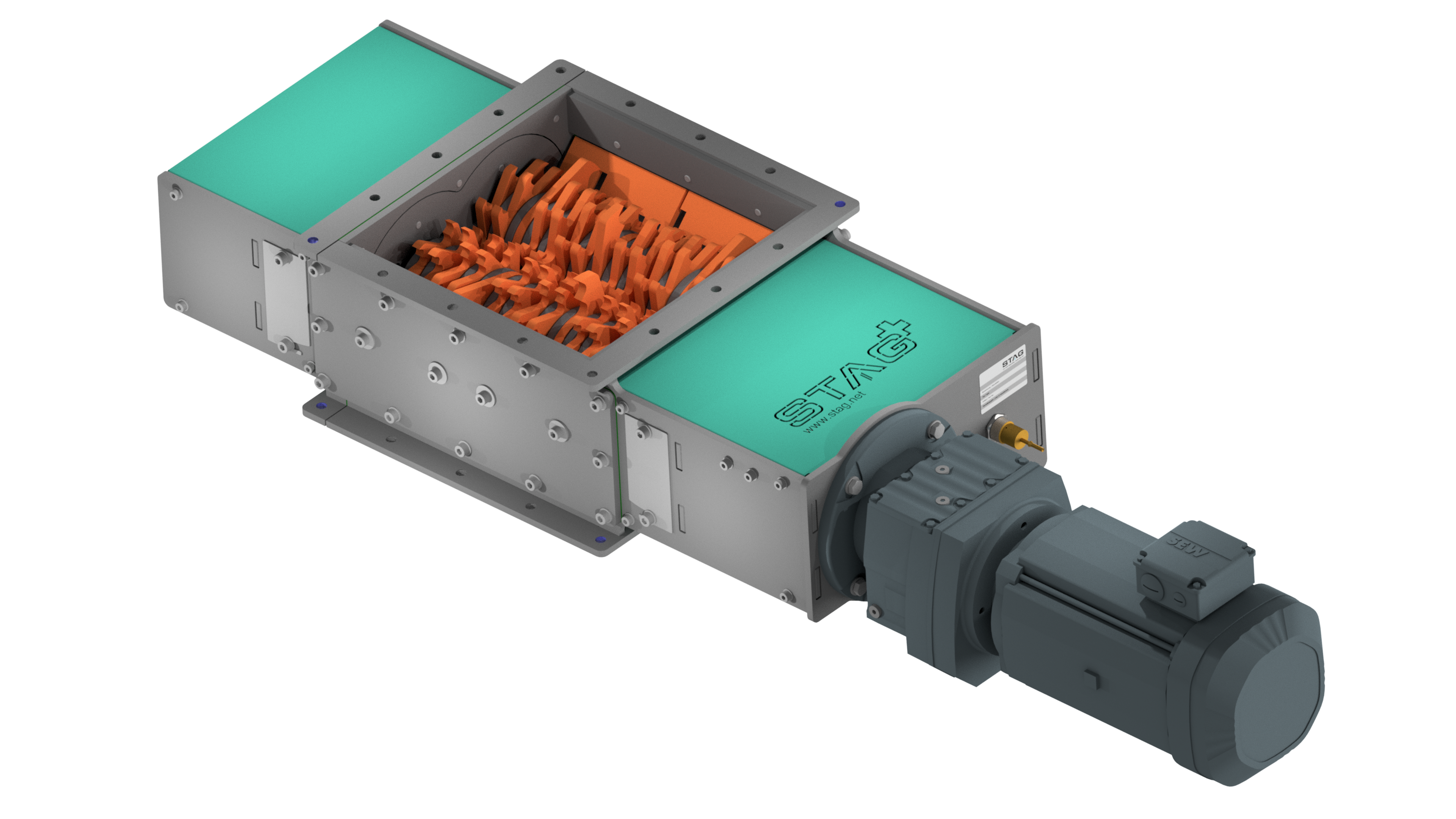

- Single-shaft and twin-shaft design

- Various blade sets for various applications

Special Characteristics – Application (USP)

- Massive Hardox blade set

- Trident for improving feeding of lumps

- Low overall height, perfect for retrofitting

- Solid welded design

- Shaft sealing with gland packing

- Stainless steel version available

Industries

- Waste to Energy

- Cement industry

- Steel plants

- Temperature resistance up to 400°C

- Different flow rates depending on the blade set used

The flow rate depends on the following parameters and must be checked for each application:

1. Bulk material properties

2. Crushability and hardness of lumps (agglomerations, caking, etc.)

3. Range of grain size (lump fraction, fine fraction)

The impact mill has been specially designed for breaking up agglomerated material within the bulk product. This application is mainly used in the treatment of boiler ash originating from incineration plants.

In 2013, a new waste-to-energy plant has been erected in the heart of Great-Britain, realising thus the 10th plant fitted with STAG systems and components on British soil.

We are happy to carry out the necessary revision of replaced machine components. Send us your aggregate to Maienfeld and we will inspect and revise it. Experienced mechanics and plant and apparatus engineers inspect the unit.