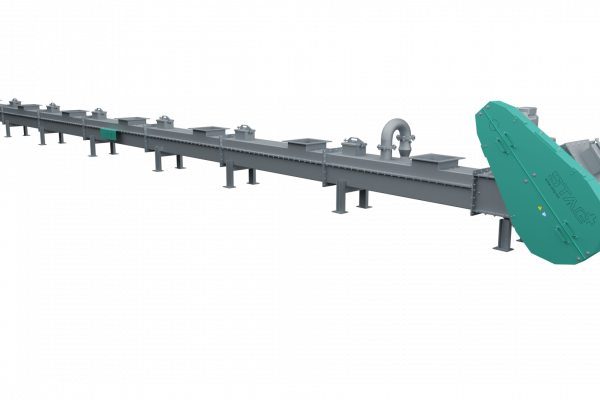

A wood-fired power plant in the east of France has relied on STAG bulk handling. The two inclined trough chain conveyors are fed directly from the incinerator and convey the hot ash to the storage silos. The storage silos were provided with all necessary discharge aids and a big bag pick-up cross. With this combination, a faultless ash removal is ensured and the customer has a simple and low-maintenance system.

Applied Main Components

- Silo 2 pcs. 10 m³ with subs. Big-Bag loading (loading carried out by customer)

- TKF 2 pcs. trough chain conveyors 490 x 15 und 20 m

Special Characteristics

- Mechanical discharge directly from the heating system

Client

- MAWERA Holzfeuerungsanlagen GmbH

| Systems | Conveying rate | Conveying distance |

|---|---|---|

| Mechanical conveying with trough chain conveyor | 0.3 t/h | 15 - 20 m |

| Systems | Grain size | Moisture content | Bulk density | Temperature | Property |

|---|---|---|---|---|---|

| Ashes arising in wood combustion | 1 < mm, individual lumps up to 15 cm | - | 0.7 t/ m³ | 300 °C | abrasive |

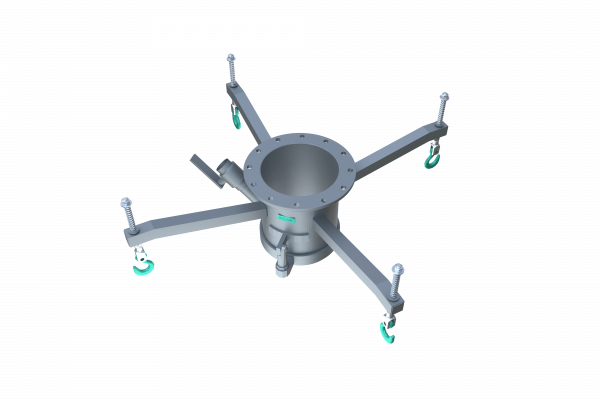

The Big-Bag Uptake Cross is a welded construction, which has been further refined by STAG during the last 50 years. The spring-loaded karabiners simplify the hanging in an out of the Big Bags. The bag clamp ensures that the dust exposure is reduced to a minimum.

Chain conveyor are continuous conveyors and are suited for the conveyance of bulk products of all kind up to small-sized products and sludges.

Each year STAG handles around 500 customer orders and achieves satisfied customers around the world. Here too, the focus lies on life-cycle-oriented warehousing as well as the plant availability. The experienced employees of the business area service are happy to answer any questions or suggestio