Injector:

Injectors are used for the simple, self-regulating in-feed of powdered and granular bulk products into pneumatic conveying lines without moving parts.

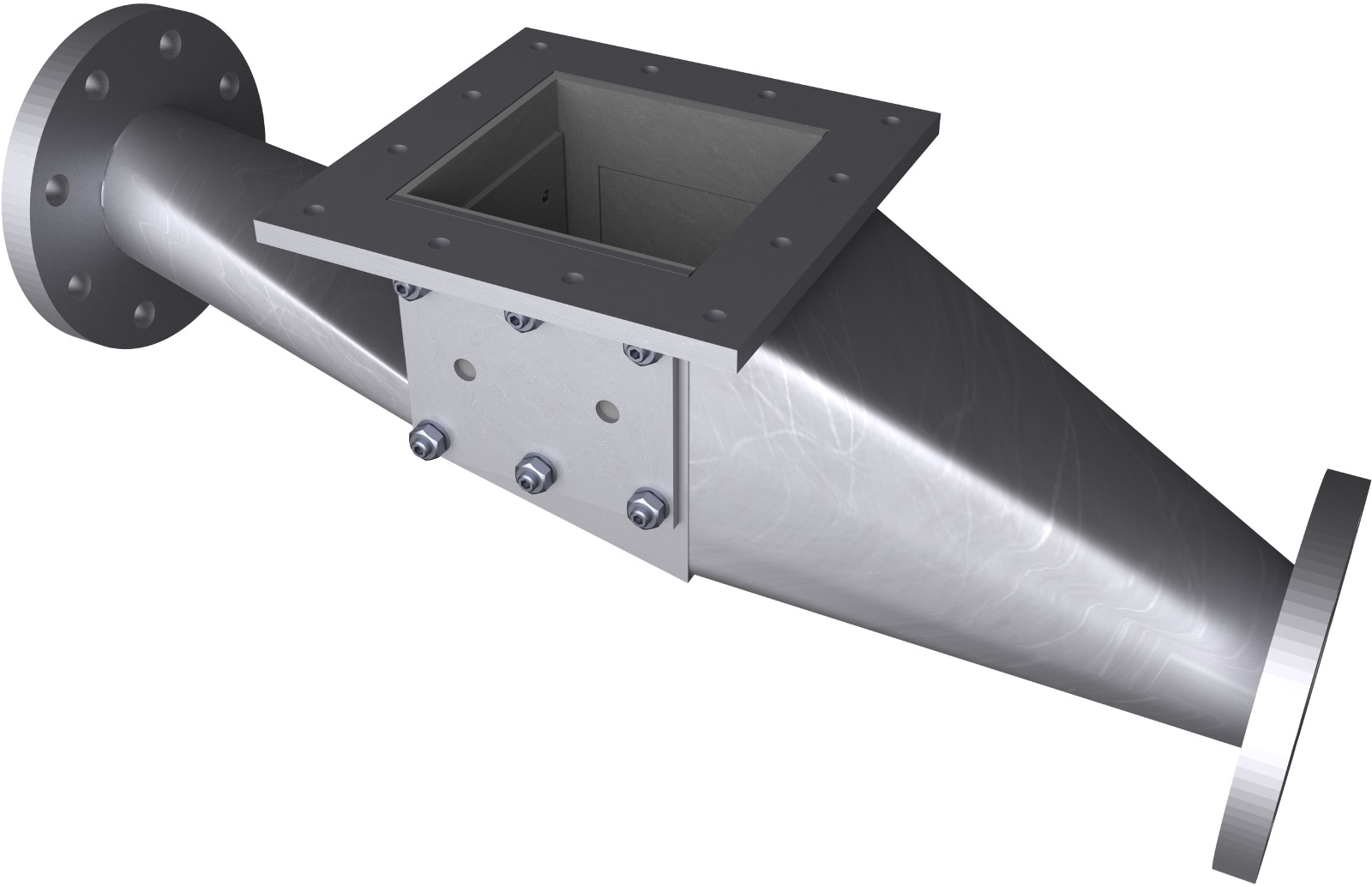

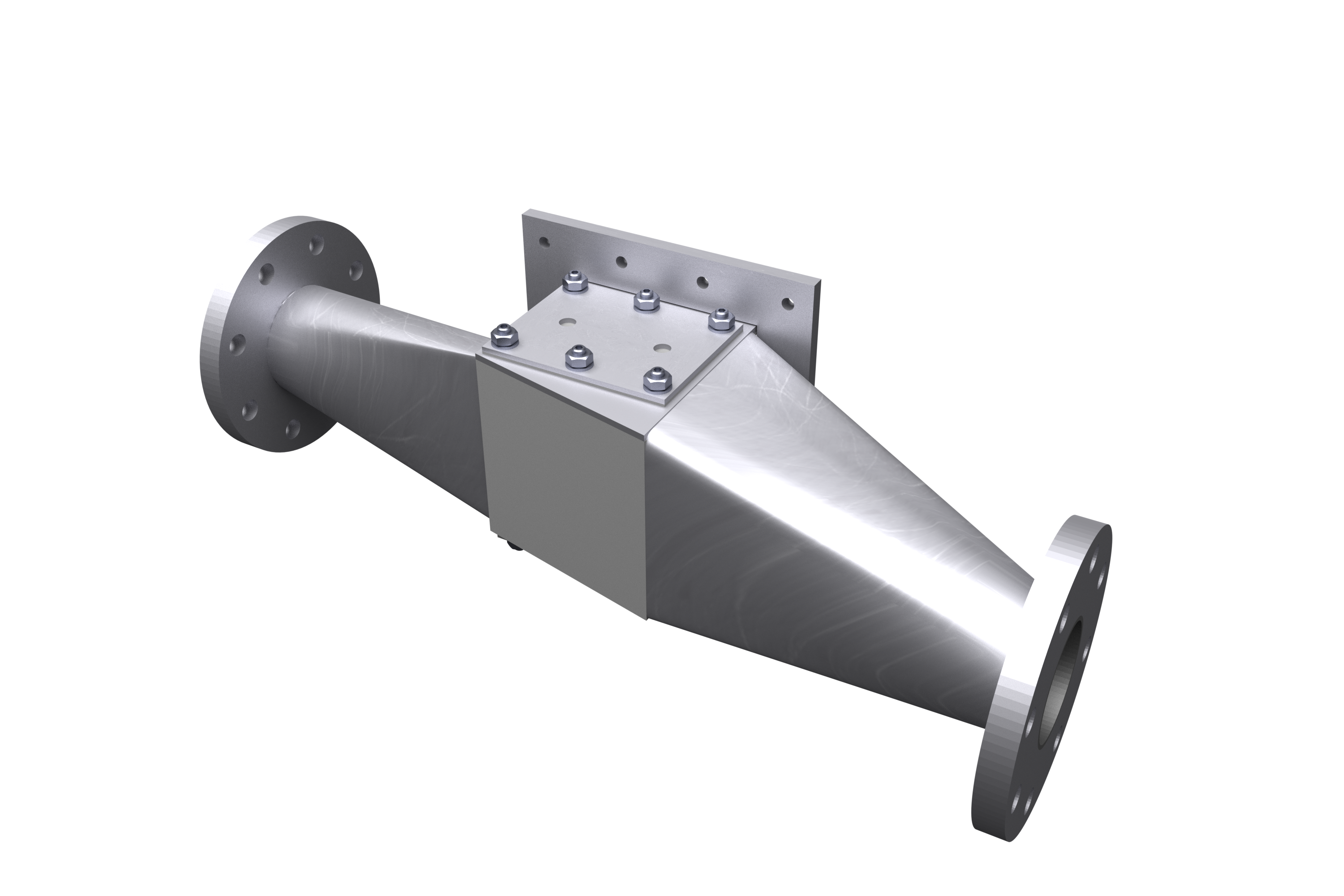

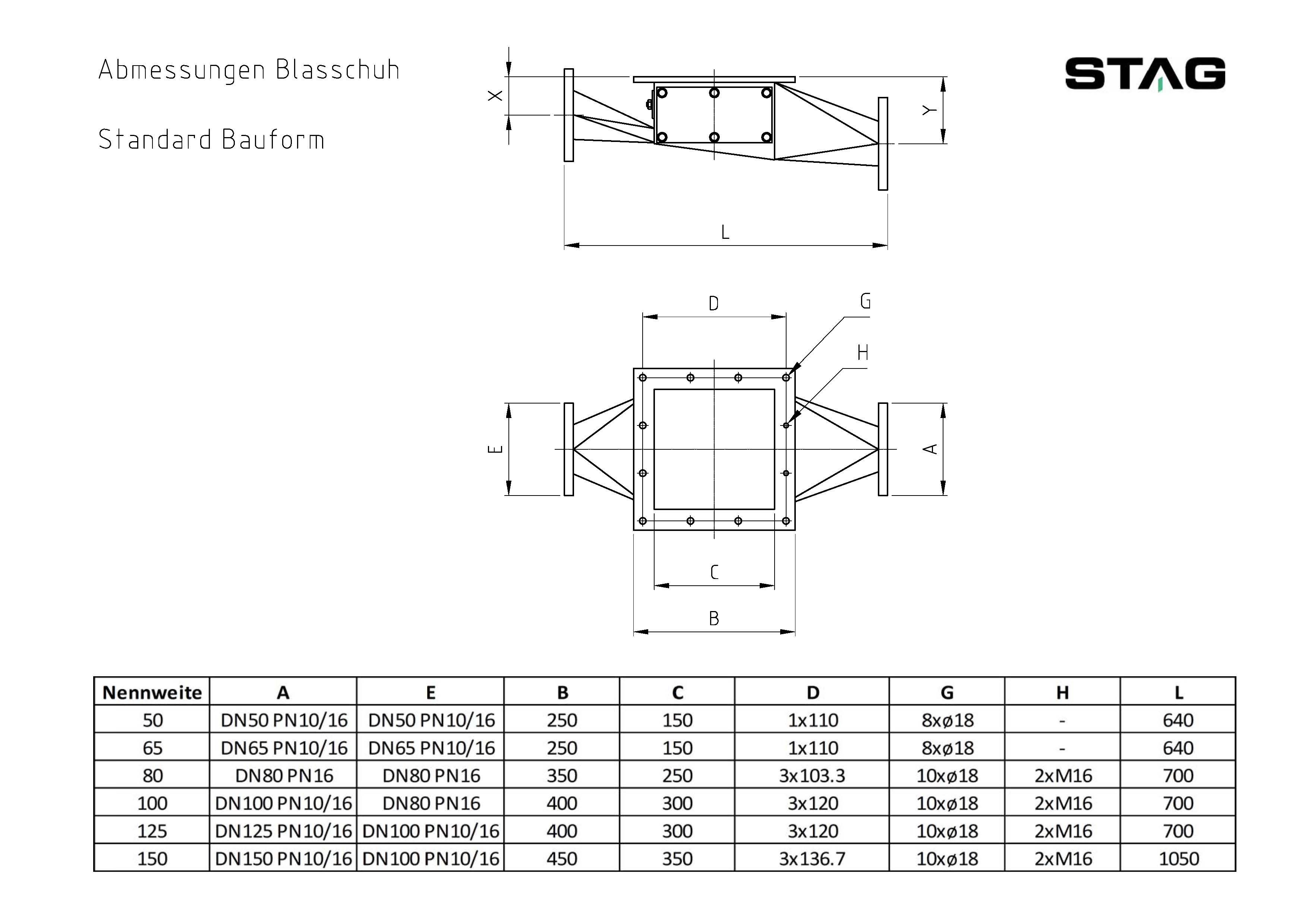

Air blast nozzle:

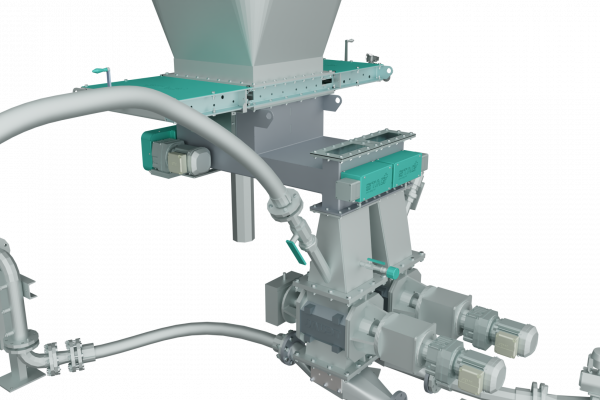

Pneumatic dilute phase conveying systems using an air blast nozzle are suited for the pneumatic conveyance of not or only slightly abrasive products. Combined to a rotary vane feeder as stop valve, both dosing and pressure sealing towards a continuous product transfer into the conveying line, ensuring, together with a minimum control effort, a high level of operational safety. Various geometric shapes of the STAG air blast nozzle range provide for smooth conveyance of most different bulk materials.

Experience

- Years of experience in use in complete systems

- Process & / bulk material specific versions possible

Special Characteristics – Application (USP)

- Special geometry for hydrated lime

- Special geometry for HOK

- Experience with complete system

Use

- Waste-to-energy

- Power plants

- Steel plants

- Construction materials industry

- Paper industry

- etc.

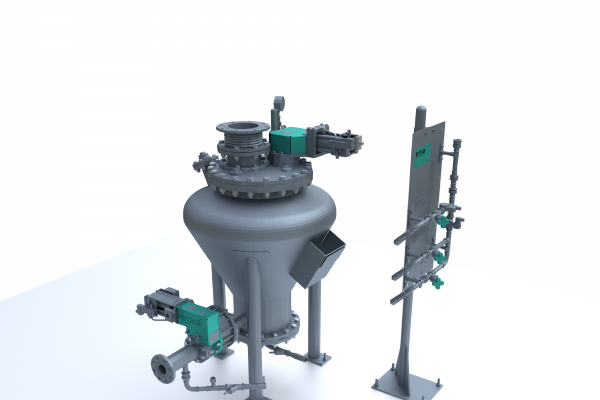

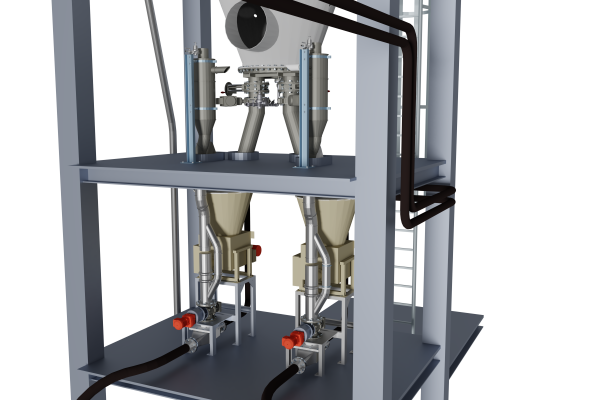

The pressure conveying vessel is used by STAG when it comes to challenging tasks, high conveying rates and long con-veying distances. This pneumatic conveying application using the dense flow method combines energy-optimised conveying processes with perfect operational safety.

STAG has gained an extensive experience with the gravimetric dosing system. The system contains the dosing, the pneumatic conveying with product-specific air blast injector nozzle as well as the necessary air treatment.

STAG has gained an extensive experience with the volumetric dosing system. The system contains the dosing, the pneumatic conveying with product-specific air blast injector nozzle as well as the necessary air treatment.