The VEOLIA energy group operating at a global scale is one of the largest providers, especially in the area of municipal waste management such as waste water and sewage sludge treatment.

Due to our long and successful relationship with VEOLIA as well as to our wide experience in the field of conveying technology, we were entrusted to supply ash removal systems also in Poland.

As a specialist company, STAG was in charge to provide conveying systems and components used for the pneumatic and mechanical ash removal of cyclones and fabric and electric filters in the newly built sewage sludge combustion plant.

The flue ashes and residues are separated in the hoppers and transported into the storage silos by means of the pneumatic pressure conveying vessels. The subsequent silo vehicle loading is ensured via lowerable loading facilities or by moistening of the flue ashes and residues in order to allow their open loading into trucks.

Applied Main Components

• Bicarbonate/hydrated lime silo including fluidisation system

• Screw conveyors

• Rotary vane feeders

• Pneumatic dilute phase conveying with butterfly valve

• Bicarbonate mill

• Pressure conveying vessel

• Conveying lines

• Silo vehicle loading station

• Mixing screw for moistening of residues

Particularities

• Moistening of flue ash and residues

Client

• Veolia Water System s.p.z.o.o.

| Systems | Conveying rate | Conveying distance |

|---|---|---|

| Bicarbonate and hydrated lime dosing | - | - |

| Residue ash removal from fabric filter plant Lodz | 0.5 t/h | 50 m |

| Pneum. ash removal from cyclone plant Lodz | 1.0 t/h | 60 m |

| Pneum. ash removal from cyclone and electric filter plant Krakow | 1.4 t/h | 115 m |

| Pneum. residue ash removal from fabric filter plant Krakow | 0.18 t/h | 65 m |

| Flue ash and residue moistening – Plant Krakow | 1.8 – 2.0 t/h | - |

• Bicarbonate/hydrated lime dosing including dilute phase conveying

• Pneumatic ash removal of Zyklon, electric and fabric filters

• Silo vehicle loading

• Flue ash and residue moistening

| Bulk material | Grain size | Moisture content | Bulk density | Temperature | Property |

|---|---|---|---|---|---|

| Flue ash from cyclone and electric filter | - | - | 0.6–0.8 t/m3 | 150 °C | abrasive |

| Residues from fabric filter | - | - | 0.35–0.5 t/m3 | 100 °C | abrasive |

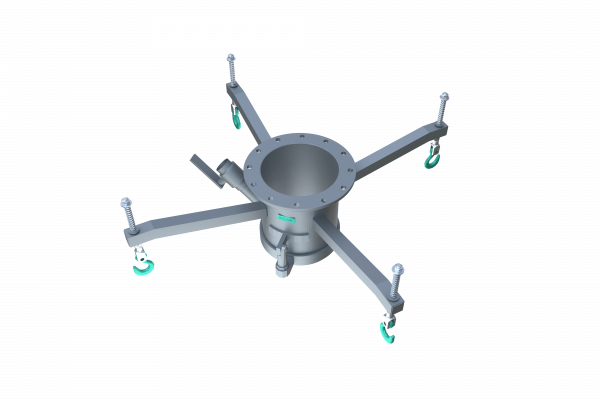

The Big-Bag Uptake Cross is a welded construction, which has been further refined by STAG during the last 50 years. The spring-loaded karabiners simplify the hanging in an out of the Big Bags. The bag clamp ensures that the dust exposure is reduced to a minimum.

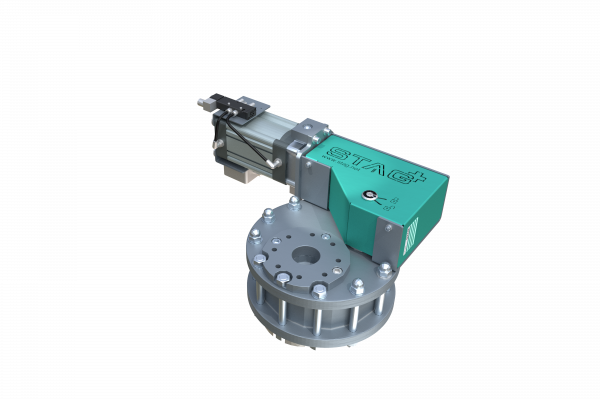

The double-sided sealing turn slide valve has been especially designed for pneumatic conveying as part of the STAG pressure conveying vessel technology. No other system can satisfy the high demands of this application.

Each year STAG handles around 500 customer orders and achieves satisfied customers around the world. Here too, the focus lies on life-cycle-oriented warehousing as well as the plant availability. The experienced employees of the business area service are happy to answer any questions or suggestio