In 2018, the existing flue gas cleaning system of the waste combustion plant SRS Ecotherm has been converted from a lime milk treatment to a conditioned dry process with hydrated lime and bicarbonate dosing.

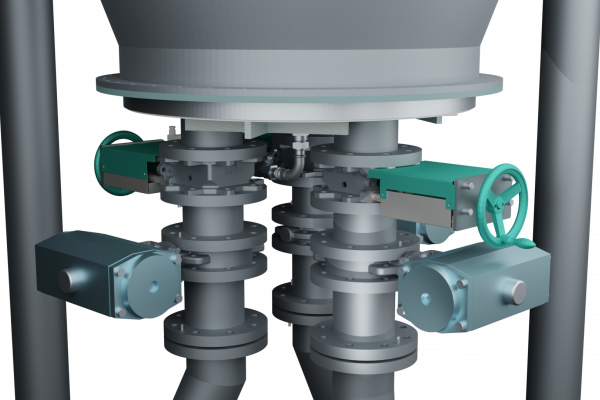

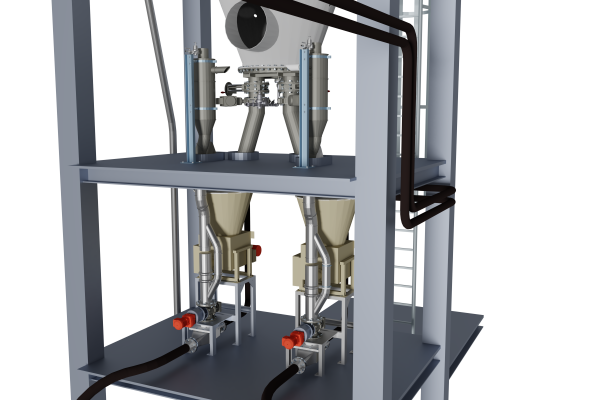

STAG supplied two identical dosing and conveying systems with subsequent pneumatic butterfly valve dilute phase conveying into the two flue gas channels.

The dosing and conveying system designed by STAG, including a butterfly valve developed for hydrated lime conveying, perfectly matches the requirements of such applications.

Applied Main Components

• Upgrade of existing hydrated lime silo with ventilation floor and fluidisation

• Gravimetric hydrated lime doing using a differential dosing scale and subsequent pneumatic butterfly valve dilute phase conveying system

• Volumetric bicarbonate dosing and subsequent pneumatic butterfly valve dilute phase conveying system

• Conveying air supply by means of rotary piston fans

• Control system including wiring

Particularities

• Conversion of existing flue gas treatment plant

• Efficient project execution in cooperation with operating company

Client

• SRS Ecotherm

| Systems | Conveying rate | Conveying distance |

|---|---|---|

| Bicarbonate NaHCO3 dosing | 0.2 - 1.1 t/h | 40 m |

| Hydrated lime Ca(OH)₂ | 0.1 - 0.8 t/h | 30 m |

- Silo discharge system including ventilation floor

- Gravimetric dosing

- Pneumatic dilute phase transport

- Plant control system

| Bulk Material | Grain size | Moisture content | Bulk density | Temperature | Property |

|---|---|---|---|---|---|

| Sodium bicarbonate | 100 % < 0.1 mm | dry | 0.6-0.9 t/m³ | ambient | not abrasive |

| Hydrated lime | 100 % < 0.1 mm | < 0.6 % | 0.36 t/m³ | ambient | not abrasive |

In addition to fluidization, STAG uses Fluid Floors for silos with multiple outlets.

The entire silo floor is equipped with a fluid cloth and enables the bulk material to be stored to flow off constantly and completely.

We are happy to carry out the necessary revision of replaced machine components. Send us your aggregate to Maienfeld and we will inspect and revise it. Experienced mechanics and plant and apparatus engineers inspect the unit.

STAG has gained an extensive experience with the gravimetric dosing system. The system contains the dosing, the pneumatic conveying with product-specific air blast injector nozzle as well as the necessary air treatment.