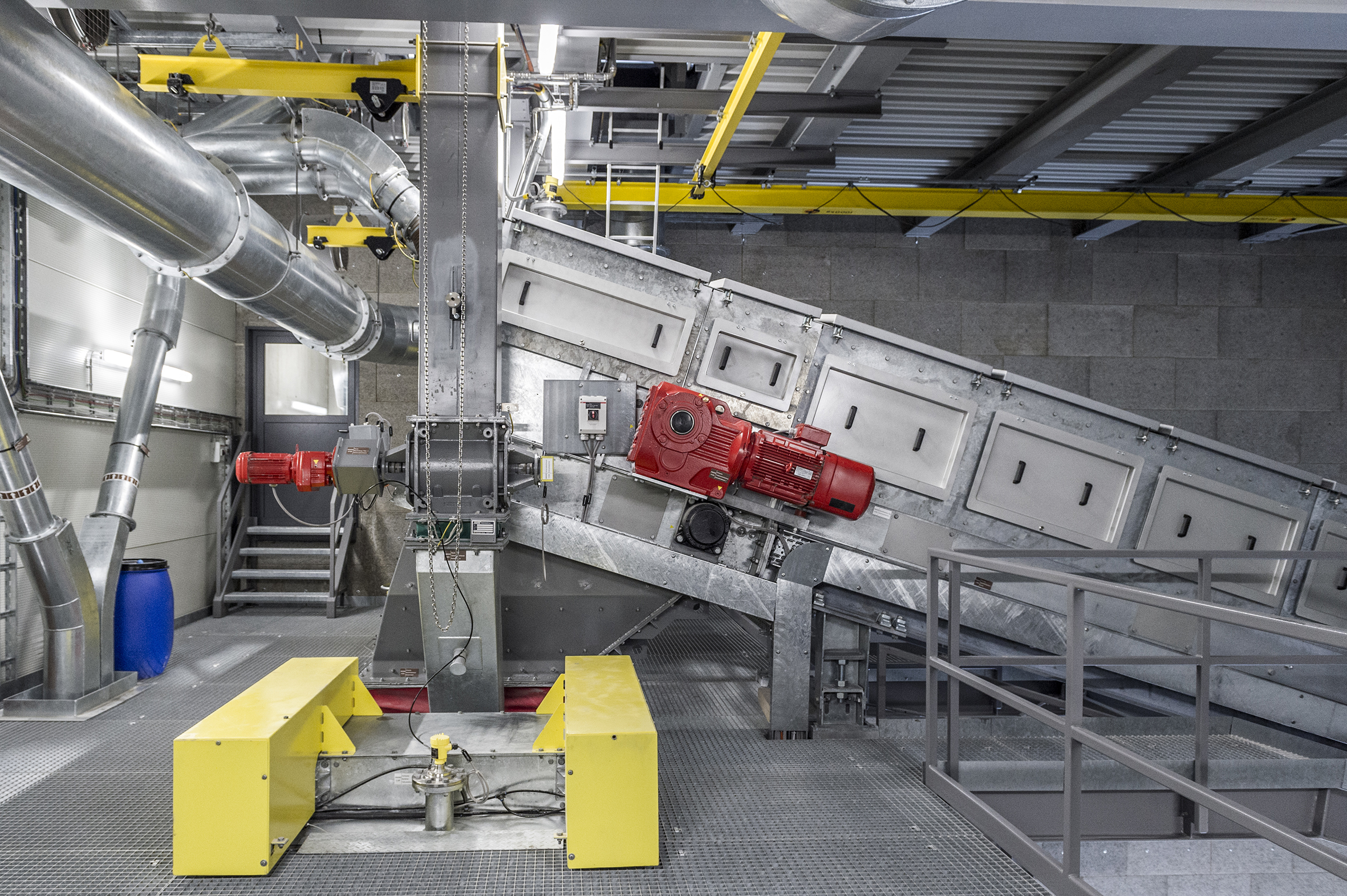

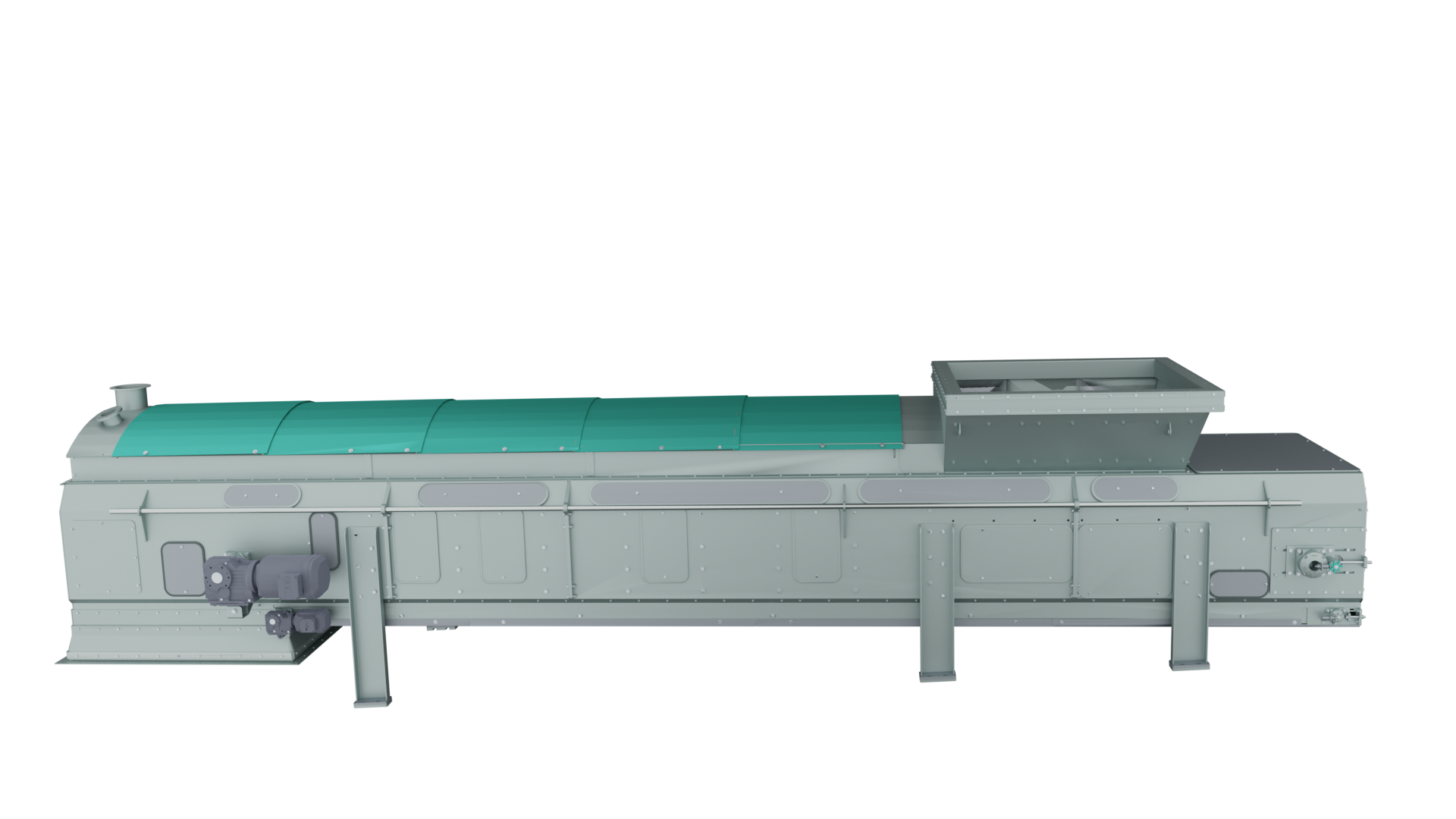

The closed STAG Conveyor Belt stands out through its dustproof design and its integrated scraper floor. With this construction method the conveyor belt can be operated by a slight vacuum.

Provided suction socket at the connectors are the interface to the dust extraction. The integrated scraper floor will be periodically connected and supports dust to the discharge point into the following aggregate. Therefore a dustproof, closed system is guaranteed.

Experience

Dry slag treatment:

- 30 pcs. CB at KEZO Hinwil (ZAV) (waste-to-energy power plant)

- 3 pcs. CB at ERZ Hagenholz

- 2 pcs. CB at KVA Horgen

Special Characteristics – Application (USP)

- Closed design, dustproof

- Self-cleaning through scraper floor

Industries

- Waste-to-energy power plants Slag treatment

- Steel industry

- Cement industry

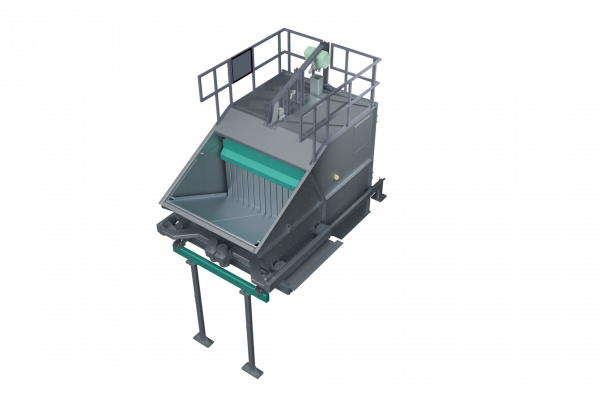

Coarse particle separators are used in mechanical conveying processes of bulk products in order to eliminate larger particles (impurities). The benefits are an improved operational safety of the conveying system, which can be reduced in size after the coarse particle separator.

We are happy to carry out the necessary revision of replaced machine components. Send us your aggregate to Maienfeld and we will inspect and revise it. Experienced mechanics and plant and apparatus engineers inspect the unit.

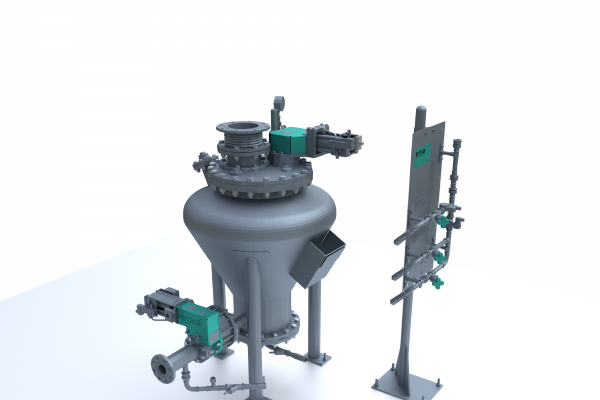

The pressure conveying vessel is used by STAG when it comes to challenging tasks, high conveying rates and long con-veying distances. This pneumatic conveying application using the dense flow method combines energy-optimised conveying processes with perfect operational safety.