In 2013, a modern coal block has been put into operation in Karlsruhe. For this project, STAG was entrusted with the engineering and delivery of the mechanical and pneumatic ash removal of the electric filter. The pneumatic conveyance facility using a tandem system provides for a continuous ash removal. The preceding mechanical trough chain conveyor therefore does not operate in a “stop and go” mode but, its gentle and low-wear operation can be ensured.

A totality of 16 pressure conveying vessels conveys the electric filter ash to the target silos via two main lines and one redundant line. These lines have been connected by means of diverter pots. The STAG Denseflow piping system ensures low-energy and low-wear conveyance.

Applied Main Components

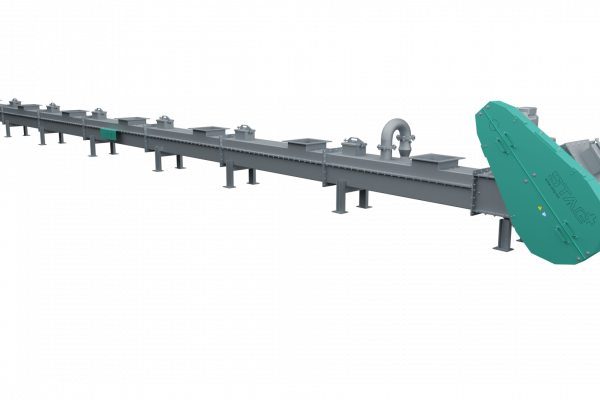

• Trough chain conveyor

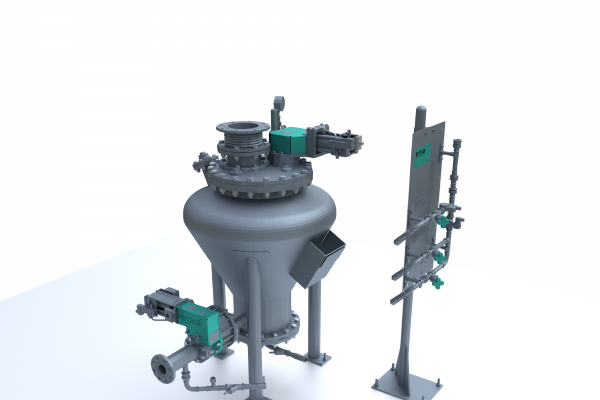

• Pressure conveying vessel

• Special piping system

Particularities

• Tandem pressure conveying vessel

• Combination of mechanical a pneumatic conveying systems

• 16 pressure conveying vessel lead to two lines

Client

• Austrian Energy & Environment AG

| Systems | Conveying rate | Conveying distance |

|---|---|---|

| Electric filter | 114 t/h | - |

| Trough chain conveyor | 8x 15 t/h | 30 m |

| Pressure conveying vessel | 16x 7.5 t/h | 280 m |

- Combination of mechanical a pneumatic transport from electric filter

- Special piping system including deflectors (STAG Denseflow)

| Bulk material | Grain size | Moisture content | Bulk density | Temperature | Property |

|---|---|---|---|---|---|

| Electric filter ash | 100% < 1mm | < 0.2 % | 0.7 - 1.0 t/m³ | 140°C | abrasive |

Chain conveyor are continuous conveyors and are suited for the conveyance of bulk products of all kind up to small-sized products and sludges.

The pressure conveying vessel is used by STAG when it comes to challenging tasks, high conveying rates and long con-veying distances. This pneumatic conveying application using the dense flow method combines energy-optimised conveying processes with perfect operational safety.

New legal requirements, specific customer requirements or the need to modernize the system are just a few preconditions for which it is worthwile to contact STAG Service. All over decades built up experience in plant construction are at your disposal.