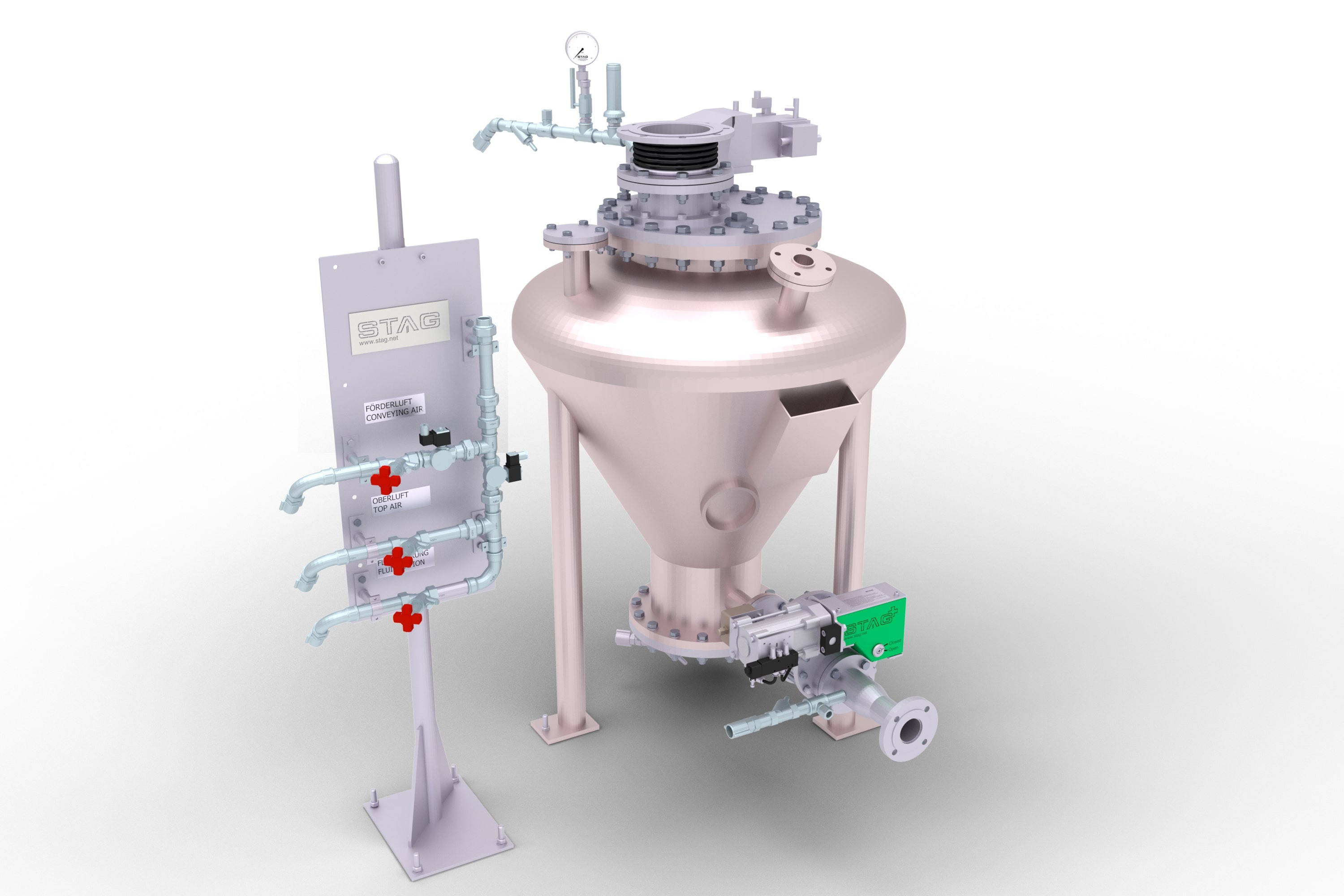

The pressure conveying vessel is used by STAG when it comes to challenging tasks, high conveying rates and long con-veying distances. This pneumatic conveying application using the dense flow method combines energy-optimised conveying processes with perfect operational safety. Combined with a suitable conveying line, the STAG pressure conveying line provides for conveying nearly any kind of bulk material.

Experience

- More than 600 completed pneumatic dense phase conveying Systems

- Realised conveying distances up to 2,300 m

- Realised conveying rates up to 300 t/h

Special Characteristics – Application (USP)

- Proven STAG inlet and outlet device MVP/ DVP

- Proven STAG dense phase conveying line for heavy bulk materials presenting a wide range of grain sizes

- Multiple setting options for each bulk material to adjust the air support

- Unloading alternatives specific to each bulk material in order to support the pneumatic conveying process

- STAG Service Support

Industries

- Waste to Energy

- Power stations

- Steel plants

- Construction materials industry

- Paper industry

- etc.

- Conveying distances up to 2,300 m

- Conveying rates up to 300 t/h

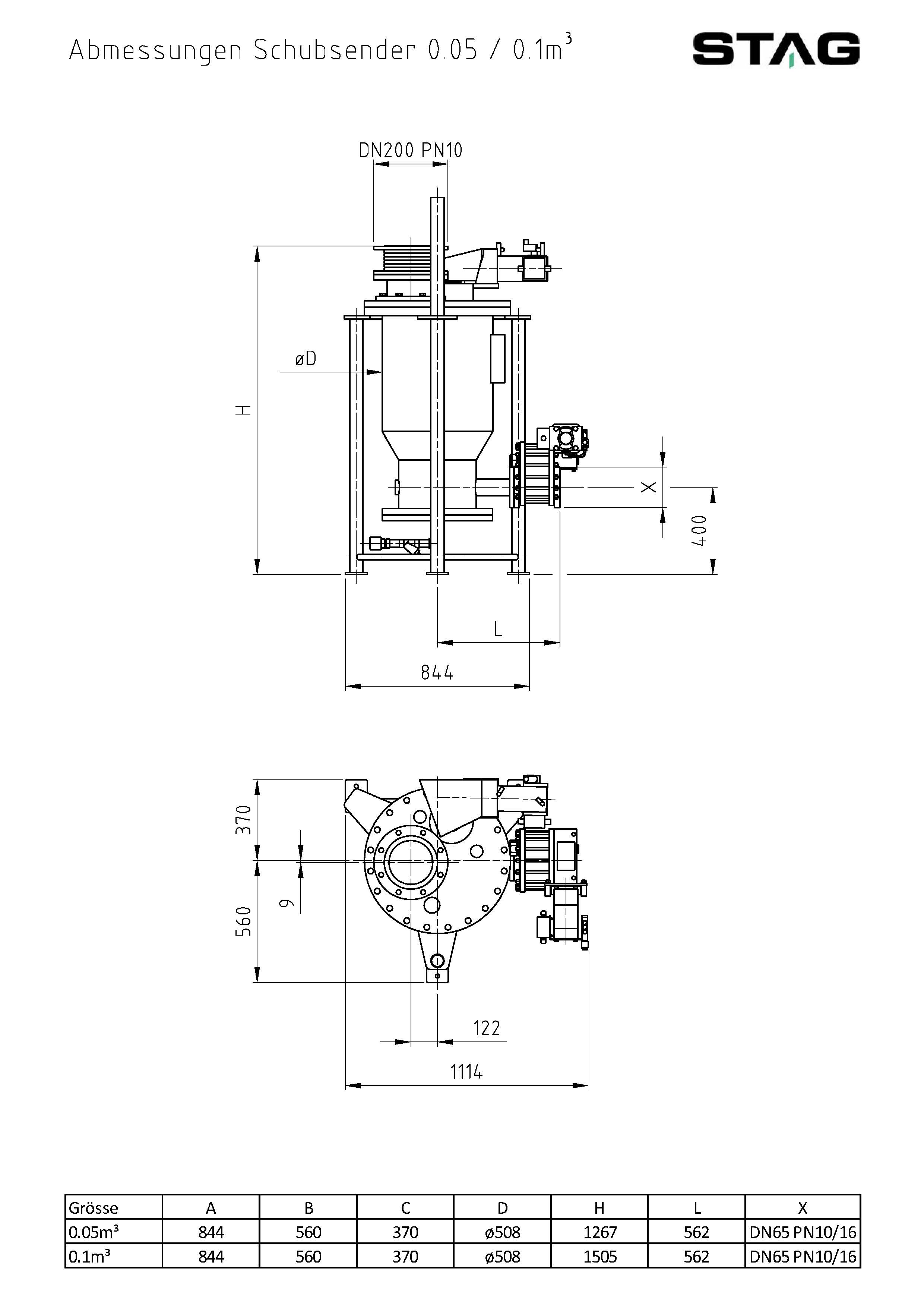

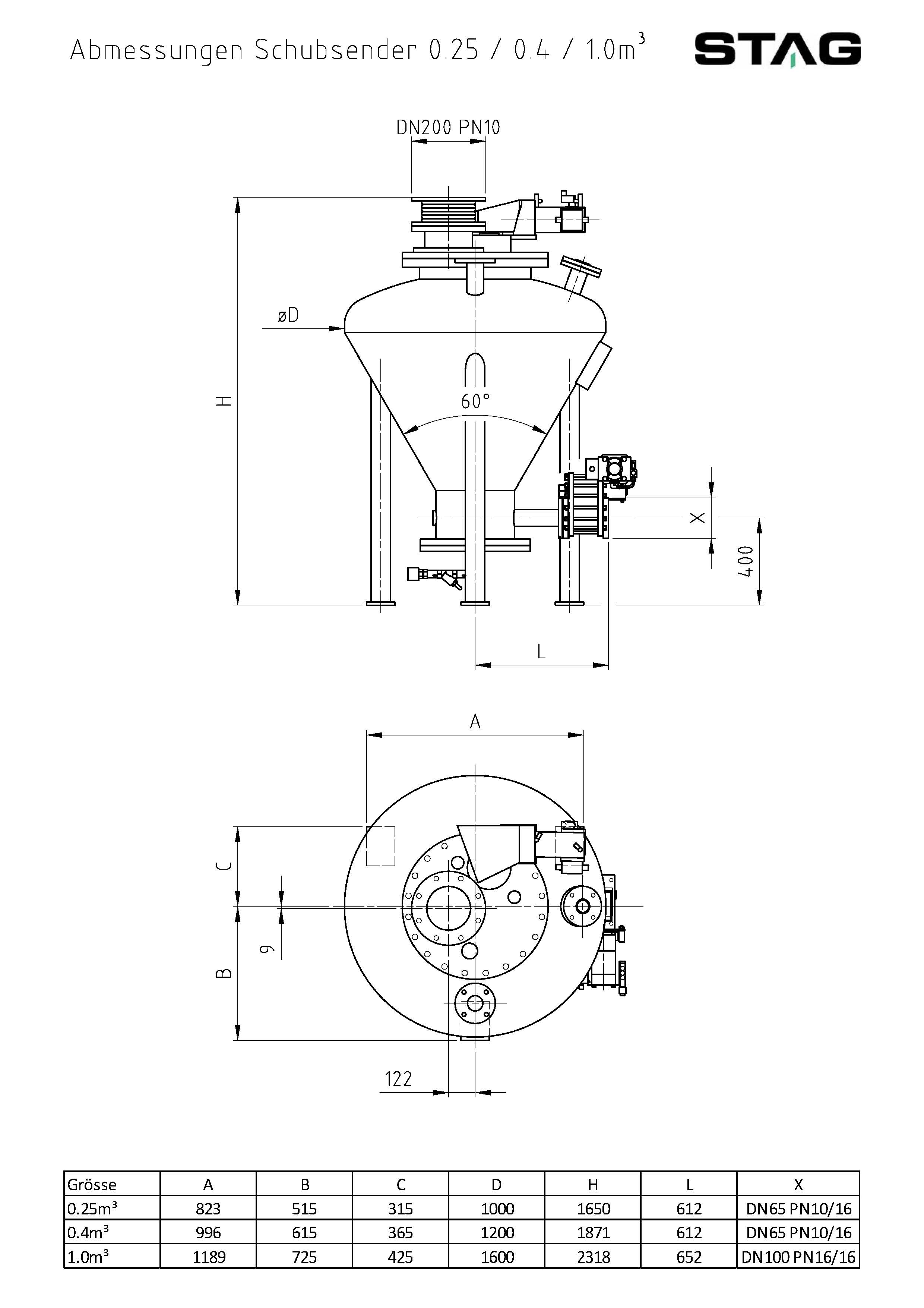

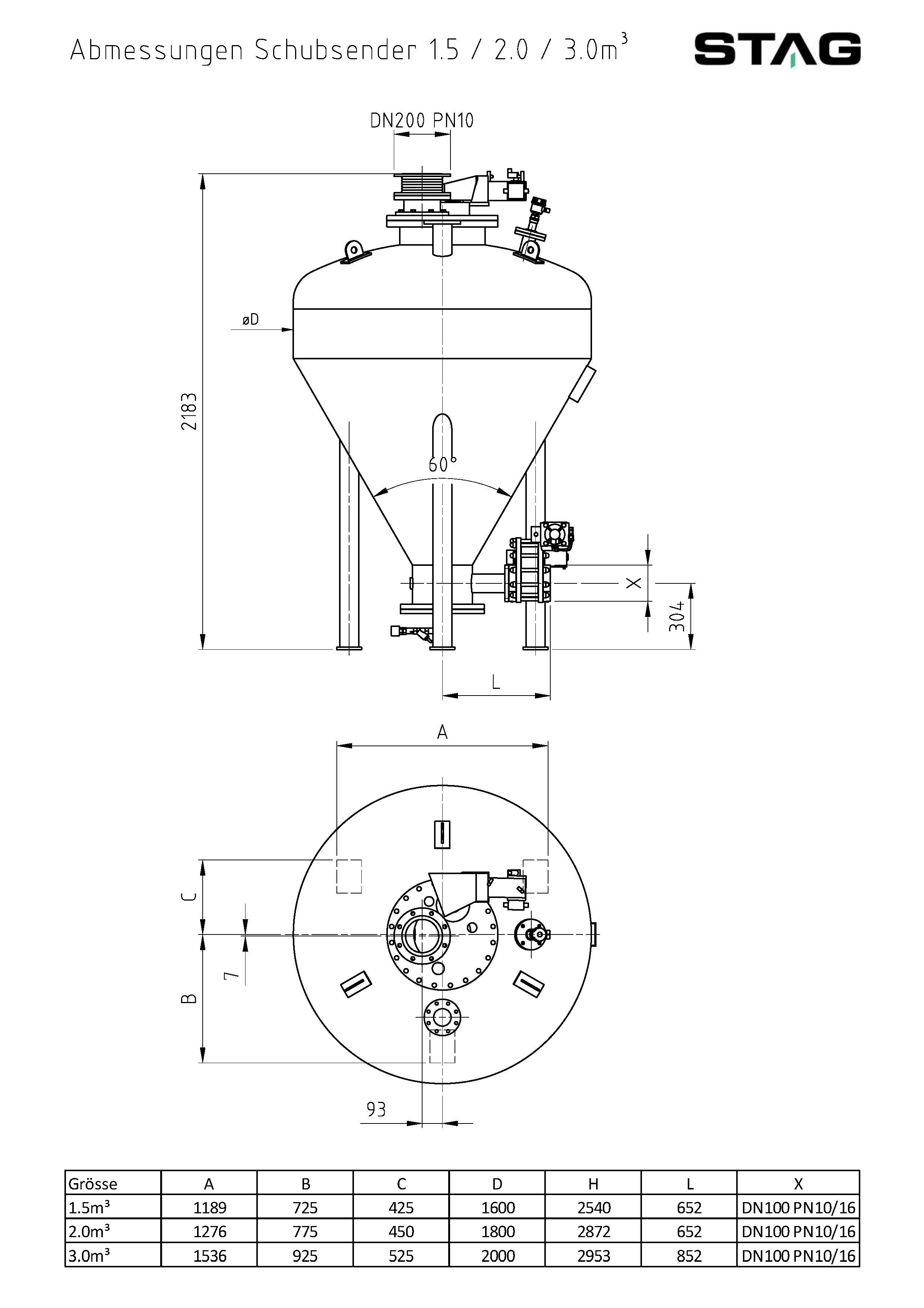

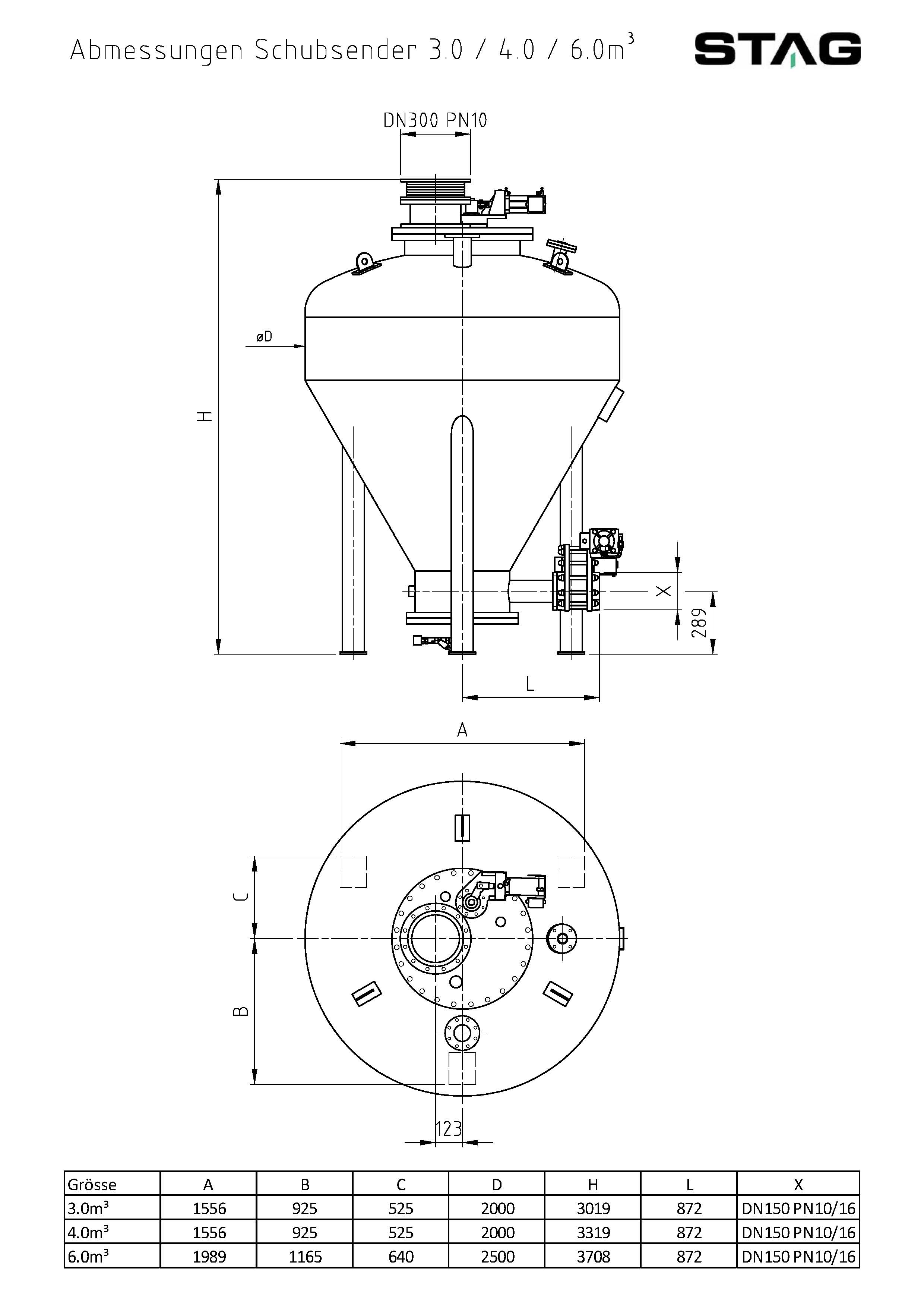

- Sizes 0.1 – 20 m³ pressure conveying vessels

- Temperature resistance up to 400°C (Standard)

- Conveying pressure up to 6 bar(ü)

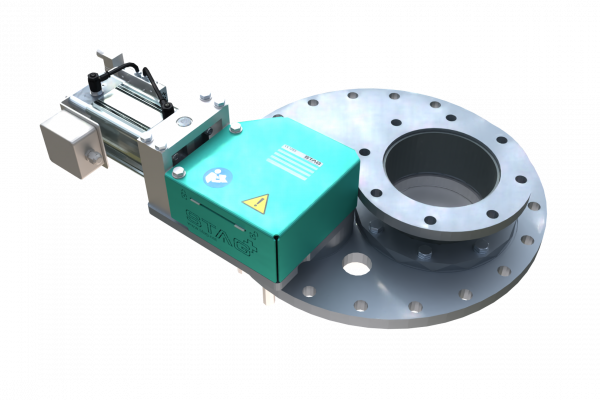

The one-sided sealing turn slide valve has been especially designed for pneumatic conveying as part of the STAG pressure conveying vessel technology. No other system can satisfy the high demands of this application.

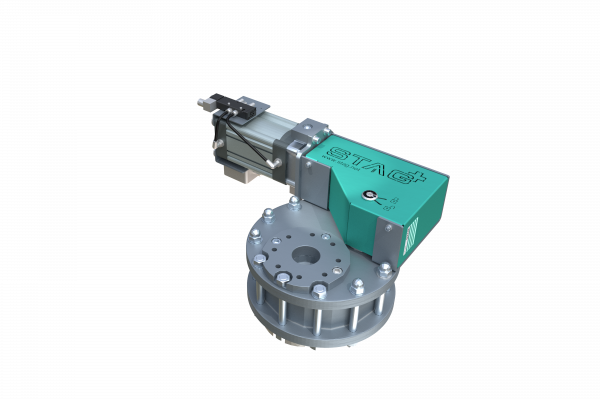

The double-sided sealing turn slide valve has been especially designed for pneumatic conveying as part of the STAG pressure conveying vessel technology. No other system can satisfy the high demands of this application.

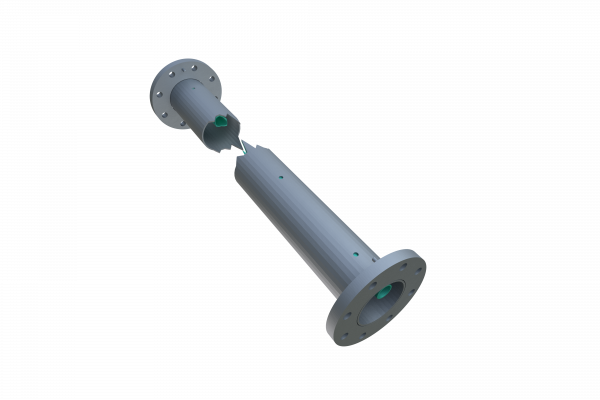

In conventional conveyances of powdered bulk materials through smooth pipes, the irregularity of the flow rises with the increasing pipe length. This in turn, increases the wear of the system.